The single-stage handloading press has been with us since about 1930, when the Pacific Reloading Company patented its C-style press. The C-style press is, in essence, an upside down arbor press that uses compound linkage as the pressing force rather than a rack and pinion. Those first Pacific presses were stout and became quite popular.

But during the late ’30s and on into the 1960s there were a lot of guys experimenting with wildcat—non-factory loaded—cartridges. Case forming became commonplace. The C-style press had too much flex for heavy-duty chores like this so the O-press was developed, which distribute the pressing force equally from two sides and have virtually no flex. As such, O-style presses became more-or-less the standard for single-stage presses.

Today much of the attention has turned toward the progressive press. Progressives complete multiple tasks with each stroke of the operating handle. Those of us who shoot a lot are well served by these marvels of engineering that can crank out up to a thousand rounds in an hour, but for the experimenter and accuracy buff a single-stage, O-style press remains a necessary tool.

Hornady has taken the O-style press and given it a face lift. Its new Lock-N-Load Iron Press did some re-engineering of the old O-press and added several new features that make it much more efficient and user friendly.

The first two changes immediately visible about this press is its heft—the bare press weighs in at a rather beefy 26 pounds—and the “O” or window is turned 90 degrees. All that iron makes sure this press will never flex under any load that could be applied by human hands alone. It also ensures that it will be all but impossible to ever wear it out. The window measures a whopping 3 9/16"—large enough to easily accommodate the Ultra Mag-length cartridges, and the ram is equally stout at 1 1/8" in diameter. Most manufacturers have now recognized there are left and right handers, and Hornady fell in line making the operating handle mount ambidextrous.

Up top there is a V-shaped bridge to the window. It is drilled and tapped for mounting screws included in the kit, or you can choose to mount primer pocket cleaners, neck brushes, inside or outside chamfering tools. There is also a handy mount for a plastic bin that will hold a box of bullets at the ready for seating. No more fishing around in a bullet box on the bench that always seem to run away from your fingers. A flat V-shaped tool holder also goes here; the V going toward the rear. This holds the dies you will be using mounted in Lock-N-Load adapters and ready for a quick change.

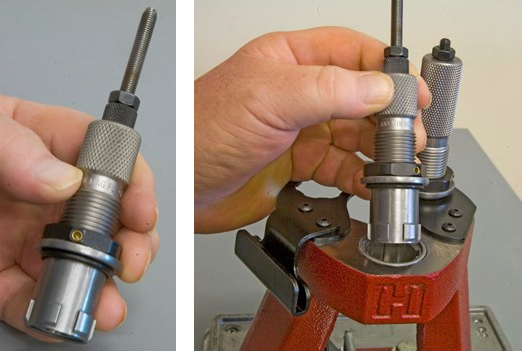

Hornady’s Lock-N-Load adapter system isn’t new. These adapters first became available in 1997. The concept is remarkably simple and easy. Screw any standard 7/8 x 14 TPI die into the adapter. The adapter drops into the press and locks with a quarter turn. Adjust the die as you normally would and lock it in place. Bingo! Now you can switch dies with nothing more than a quarter turn in or out instead of laboriously screwing them in or out each time you use them. For those in cramped quarters, you can even screw Hornady’s volumetric powder measurer in a Lock-N-Load adapter and run it on the press. Don’t try to store the powder measure in the tool holder though. It isn’t set up for something so top heavy.

A real innovation is the automatic priming assembly. It can be purchased already mounted to the press—like the model I had—or it can be added later. The automatic priming system stores primers in a typical primer tube staged above the shuttle assembly. What makes this a bit different is the steel tube shroud that fits over the primer tube and screws into the base of the press. A plastic top centers the tube within a tube, making primer feeding more reliable. The external tube also—perhaps most importantly—shields the operator in the event of primer detonation within the primer tube. It has never happened to me in loading more than 100,000 rounds of ammunition, but I know several who have experienced primer detonation. Think of it as something you really want to avoid. This shield is a great addition, and unlike a lot of safety additions, it doesn’t interfere with normal operations.

I mounted the press on my portable loading bench—the one I use occasionally for handloading seminars—and put together some test loads in .300 Win. Mag. featuring Hornady’s new ELD-X hunting bullets. About the only criticism I have is the powder measure would not throw consistent charges of the Hodgdon H1000 powder I was trying; I had to trickle and weigh every charge. To be fair, a lot of volumetric powder measures suffer this same malady. The rest of the system performed flawlessly, though, and I was thoroughly impressed. As I write this I am awaiting a dry day to go to the range and shoot these cartridges, but I am confident they will be fine.

You can purchase the Lock-N-Load Iron Press alone sans the automatic priming system for an MSRP of $269, or the kit form which contains the automatic priming system, die caddy, component feed bin and bracket, digital scale, case prep accessories (chamfer and deburr tool, large and small primer pocket cleaners, neck brushes: .22 cal., .25 cal., 6 mm, .270 cal./7 mm., .30 cal., .35 cal. and .45 cal.), powder measure, current reloading handbook, a tub of Unique Case lube, Lock-N-Load Comparator set of six, a three-pack of Lock-N-Load Die Bushings, powder funnel (.22 to .45 cal.), digital caliper and a shell holder kit (#1, #2, #5, #16, #35) for an MSRP of $619. Street prices will undoubtedly be a bit lower. For more information go to, hornady.com.