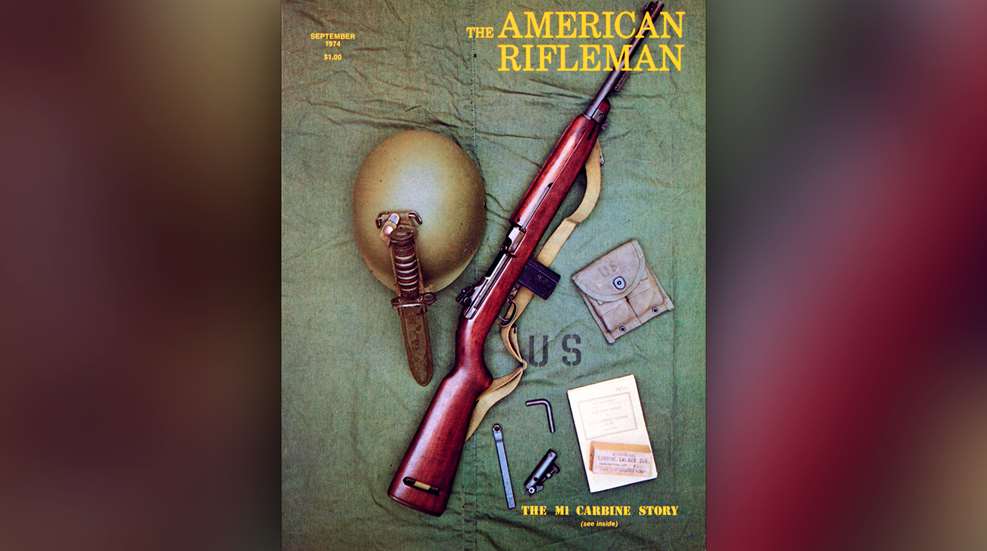

This article appeared originally in the September 1974 issue of American Rifleman. To subscribe to the monthly magazine, visit NRA’s membership page.

To the American GI of World War II, it was usually a case of love at first sight when he was introduced to the trim little M1 carbine, and especially so if his shoulder ached from lugging a 10-lb. M1 rifle over hill and dale. Often called the "baby Garand" by the troops, the Winchester-designed M1 carbine with its variations was produced in greater quantities than any other U.S. military small arm. In the hands of American and Allied soldiers, it added punch to the all-out offensive against the Axis powers.

American industry manufactured the astounding total of 6,117,827 carbines of all types from 1942 through 1945. This was a production miracle by any standard. If laid buttplate to muzzle, they would have extended for more than 3,400 miles, or some 600 miles farther than the airline distance between Seattle, Wash., and Miami, Fla.

The speed with which the M1 carbine was developed and readied for quantity production is a striking tribute to the energy and patriotism of everyone involved, and especially to Major (later Colonel) Rene R. Studler, Ordnance Department, chairman of the Ordnance Subcommittee charged with the development of the new arm, who guided the operation through to its successful conclusion.

The genesis of the M1 carbine goes back to the aftermath of World War I when all major powers reappraised their infantry small arms. In this country the need for a weapon intermediate between the standard infantry rifle and pistol was realized, but there were differences of opinion as to the form it should take. As an expedient, perhaps, the U.S. Army adopted the Thompson submachine gun in 1932. Chambered for the .45 ACP cartridge, and capable of both semi-automatic and full-automatic fire, this arm was regularly furnished with both a 50-round drum magazine and a 20-round box magazine. Although popular with the troops, it was both heavy and awkward to carry. A serious tactical disadvantage was that it was chambered for a pistol cartridge with limited effective range.

In March, 1938, the Chief of Infantry stated the need for a suitable light rifle to the Chief of Ordnance, noting that approximately one out of every five combat soldiers would be serving some form of special weapon or carrying ammunition for them and could not be encumbered with the standard service rifle. The fire power of the infantry rifle company was then being increased substantially by the -inclusion of organic light machine guns and 60 mm. mortars.

In the search for a suitable lightweight intermediate arm to increase both the defensive and offensive capabilities of infantry and to arm supporting troops, Infantry Board tests had been made with pistols and revolvers both with and without holster-type shoulder stocks, but these short-range arms did not meet the requirements. In spelling out the desired characteristics for the proposed new weapon, the Chief of Infantry stressed that it should have an effective range of at least 300 yds.

In September, 1938, the Chief of Infantry wrote to the Adjutant General, again citing the need for a special infantry weapon. Subsequently, the recommendations of the Infantry Board were placed before the Ordnance Department Technical Committee where they were considered carefully.

The characteristics of the rifle proposed by the Chief of Infantry were as follows:

- Weight of the rifle with 20 rounds of ammunition was not to exceed 5 lbs.

- It should have an effective range of at least 300 yds.

- It should be magazine-fed.

- Semi-automatic functioning was essential, and full-automatic fire was desirable.

- It should be fitted with a sling so that it could be carried over the shoulder

The problem of ammunition supply for the proposed light rifle was considered by the Ordnance Department to be of critical importance, and it was felt that any benefits accruing from the weapon would be offset by the additional difficulties in supplying its special ammunition. Thus, the proposal for the new light rifle was tentatively set aside by the Ordnance Department, and it was suggested that a commercial rifle might offer a satisfactory alternative as the basis for development of a suitable military light rifle.

During the ensuing year and a half, the using services again repeated their requirement for a light rifle, but nothing came of this until the exploding war in Europe brought this need into sharp focus. In particular, the extreme vulnerability of rear area establishments to airborne and armored thrusts became a matter of grave concern. When the request for a light rifle was broached again in 1940 by the Chiefs of Infantry and Field Artillery, it was approved by the Secretary of War Aug. 27 of that year and the-Chief of Ordnance was directed to develop a suitable light rifle as soon as practicable. It was noted again that a modified commercial rifle might prove suitable.

The characteristics of the proposed light rifle were substantially identical to those outlined by the Chief of Infantry in 1938. It was desired that it be capable of both semi- and full-automatic fire and that its weight not exceed 5 lbs. The fire selector system was to be controllable by an adjustment not conveniently accessible to the user; a special tool or key was suggested to change the selector system for the type of fire needed, thereby placing the full-automatic fire capability under the direct control of unit commanders to maintain fire discipline and conserve ammunition.

The optimum cartridge capacity for the magazine was in doubt, but this was reconciled by a requirement calling for tests of magazines holding from 5 to 50 rounds.

A realistic accuracy requirement established for the light rifle called for service accuracy comparable to that of the standard infantry rifle up to 300 yards. Service accuracy at that time was defined as the ability of a rifle to consistently group its shots within a 2-ft. square at 300 yards.

Author carried an M1 carbine as a staff officer in 70th Tank Bn., 1st Cavalry Division in the Korean War. Here he examines U.S.M4E8 medium tank damaged by Chinese anti-tank mine near Chorwon, N. Korea, Sept., 1951.

Author carried an M1 carbine as a staff officer in 70th Tank Bn., 1st Cavalry Division in the Korean War. Here he examines U.S.M4E8 medium tank damaged by Chinese anti-tank mine near Chorwon, N. Korea, Sept., 1951.

In October, 1940, the Ordnance Department prepared an information circular for distribution to gun designers and commercial arms manufacturers. Entitled "Military Characteristics For Light Weight, Semi-Automatic Rifle As Possible Replacement For Caliber .45 Pistol And Sub-Machine Gun", this circular was sent to over 25 individual gun designers and arms manufacturers. Accompanying it were drawings giving maximum cartridge and minimum chamber dimensions.

Concurrent Cartridge Search

In seeking a suitable cartridge for use in the new rifle a survey of commercial and military rounds was made, but none proved suitable. Among cartridges considered were the 9 mm Luger, .38 ACP, and .45 ACP. The .32 Winchester Self-Loading cartridge came the nearest to meeting the requirements and formed the basis for the projected round. The initial specifications for the cartridge. designated "Cartridge, Caliber .30, Short Rifle, M1", were drawn up by the Winchester Repeating Arms Company and the Ordnance Department. Its general characteristics were as follows:

Bullet weight—110 grs.

Charge weight—14.5 grs. IMR 4227

Primer—Winchester No. 116

Chamber Pressure—31,000 p.s.i.

Muzzle Velocity—1,860 f.p.s.

It is highly significant that the specifications called for a noncorrosive primer as all other U.S. military small arms ammunition was then being assembled with corrosive primers. The insistence on a noncorrosive primer for the new cartridge ultimately saved the taxpayers millions of dollars. Had the ammunition been corrosive-primed, untold numbers of carbines would have deteriorated rapidly from rusting under the rigors of combat, and soon would have failed to function despite the anti-corrosive qualities of the stainless steel gas piston. This was borne out later in tests of the M1 carbine with specially-prepared corrosive-primed ammunition. In retrospect, an effective and reliable gas-operated semi-automatic carbine could not have been developed in the short time available unless a noncorrosive primed cartridge had been used.

The initial procurement order for the new cartridge given the Winchester Repeating Arms Co. called for the manufacture of 250,000 rounds. No lubricant was specified for the cartridge since it was desired that the proposed rifle not require lubricated ammunition.

The information circular sent out by the Ordnance Department in October, 1940, had set Feb. 1, 1941, as the date for submission of trial arms, but problems in manufacture of the ammunition caused this date to be advanced to April 1, 1941, and then to May 1, 1941.

Ordnance Subcommitee Appointed

To provide for trial of rifles that might be submitted, the Chairman of the Ordnance Technical Committee appointed an Ordnance Subcommittee on April 16, 1941. Chairman of this committee was Major Rene R. Studler, Ordnance Department. Membership of the Subcommittee included representatives of the Infantry, Cavalry, Field Artillery, Armored Force, and the Ordnance Corps.

The Ordnance Subcommittee met May 1, 1941, in the Social Security Building in Washington, D.C. Pilot model arms were submitted by the following:

Springfield Armory

Savage Arms Corp.

Colt's Patent Fire Arms Mfg. Co.

Harrington & Richardson Arms Co.

Auto-Ordnance Corp.

Woodhull Corp.

Bendix Aviation Corp.

John H. Murphy.

The Subcommittee was charged with examining the arms and determining those suitable for subsequent engineering testing at Aberdeen Proving Ground. A 10-phase test program was designed to determine the general serviceability of the various rifles submitted. It covered such factors as disassembly procedures, muzzle flash, recoil velocity and energy determinations, relative accuracy, endurance firing, full-automatic firing, and performance under dusty conditions.

Major (later Colonel) Edwin H. Harrison, Ordnance Department, a member of the Subcommittee (presently Senior Technical Advisor of The American Rifleman) had direct charge of the Aberdeen Proving Ground tests of all rifles. He supplied an officer who provided Proving Ground support to the Service tests conducted later at the same place. He thus had more immediate knowledge of the development than any other one person, and made this knowledge available in the writing of this account.

Of the nine rifles presented to the Subcommittee, seven were accepted for the preliminary test. Two rifles were submitted by Springfield Armory, one being blowback operated. Designed by Clarence E. Simpson, it weighed 6 lbs. 10 ozs. with its 18-round magazine. Although capable of full-automatic fire with conversion, the Simpson rifle was rejected because of its excessive weight and the fact that its design precluded reduction in weight to bring it within the 5-lb. weight limit. Springfield Armory had expected this, but had prepared and submitted the rifle so that the feasibility of a blowback-operated action for this requirement might be explored.

The other Springfield Armory rifle was gas operated. Designed by John C. Garand, it featured a top magazine feed. The magazine was canted 30° to the right and the sights were offset to the left. Ejection was from below. The top feed system permitted the use of box magazines holding up to 50 rounds.

By use of a screwdriver or nose of a pointed bullet, the fire selector could be changed from full-automatic to semiautomatic and vice versa. Partial disassembly of the rifle was required to change the fire selector mechanism. Manufacturing cost of this rifle was estimated to be approximately one fourth that of the M1 rifle. The rifle was short and handy and the design was simple, with only 41 parts. As first submitted, its weight was 5 lbs. 6 ozs. including sling and 5-round magazine. Barrel length was 16". Accuracy of the rifle in subsequent trials at Aberdeen Proving Ground was satisfactory at 100 yards and outstanding at 300 yards.

The Savage rifle weighed 5 lbs. 10 ozs. with sling but not including the magazine. It was furnished with 10-round box magazine, two 20-round circular magazines, and a 50-round circular magazine. Its operating mechanism was based on the Browning long-recoil system similar to that of the Remington Model 8 and Model 81 semi-automatic rifles, and Browning-type long-recoil shotguns except for omission of the barrel friction brake. The Savage rifle was composed of 83 parts, including all screws, pins and springs. It was slow to assemble and disassemble, but its performance was good. Accuracy at 100 and 300 yards was excellent.

The Colt rifle, designed by Val A. Browning, was of multiple-weight, blowback-operated type. It weighed 5 lbs. 8 ozs. with its 10-round magazine. The barrel was only 10 3/8" long. Weights in rear of the recoiling parts were divided so that the work of stopping the moving parts was dispersed slowly against the firer's shoulder. It was claimed that this construction reduced .the felt recoil and made the operating mechanism more durable.

The trigger mechanism of the Colt rifle was of unusual, double-stage design in which the first pull gave semiautomatic fire only. Heavier pressure had to be applied to the trigger to make the rifle fire continuous bursts. When the last shot had been fired, the magazine dropped free from the receiver. By removing a screw, the empty magazine would remain in place. Because of unforeseen circumstances, the Colt rifle was not offered for trial at Aberdeen Proving Ground.

The Harrington & Richardson rifle, designed by Eugene C. Reising, weighed 6 3/4 lbs. and was blowback-operated. It was essentially a modification of the Reising cal. .45 submachine gun then being manufactured by Harrington & Richardson. Cyclic rate of fire was about 600 rounds-per-minute. There were approximately 48 parts and these would have been unusually easy to manufacture. Shooting accuracy of this rifle was satisfactory.

The rifle submitted by the Auto- Ordnance Corp. weighed 5 lbs. 5 ozs. with 20-round magazine and muzzle brake. Its operating mechanism was of short-recoil type and a special tool was required to change the fire selector mechanism. Cyclic rate of fire was estimated to be about 600 rounds-per-minute. Its locking system was based on the Thompson principle in which a bolt lock dropped from the breechbolt to lock that part into the receiver. Accuracy of the Auto-Ordnance rifle at both 100 and 300 yards was excellent.

Blowback-operated, the rifle submitted by the Woodhull Corp. weighed 5 lbs. 13 1/2 ozs. less sling and magazine. It was furnished with 5-, 10-, 15-, 20, and 35-round magazines. F. W. Woodhull, the designer, pointed out that it was based on a simple adaptation of the Winchester Model 1905 self-loading rifle, the conversion having been done by the firm of Griffin & Howe. Its cyclic rate of fire was 550 rounds-per-minute. There was an integral muzzle brake in the barrel. Accuracy and functioning of the Woodhull rifle were not entirely satisfactory, and the heavily weighted bolt striking the back of the receiver gave an unpleasant, jolting quality to the recoil.

George J. Hyde designed the gas-operated rifle presented by the Bendix Aviation Corp. This rifle weighed 6 lbs. 2 ozs. with 10-round magazine and leather sling. In this system the operating gas was tapped off the barrel approximately 5 1/2" from the muzzle, and the mechanism was extremely well made. A special tool was required to change the fire selector mechanism. Of uncomplicated design, the Hyde rifle functioned satisfactorily. Accuracy at 100 yards was excellent, but dispersion at 300 yards was excessive.

The rifle offered by John J. Murphy was designed by J. C. White and had been tested previously by the Ordnance Department as a full-size infantry rifle. Of .276 caliber, it met none of the requirements established for the proposed light rifle so was not approved for trial at Aberdeen Proving Ground.

Firing tests for acceptable rifles were scheduled to be held May 8-31, 1941, with three days allocated to each rifle. At an Ordnance Subcommittee meeting May 29, 1941, it was decided to remove the necessity of full-automatic fire from the performance requirements as testing had revealed a lack of controllability in full-automatic fire. With the elimination of the full-automatic fire requirement, the requirement for a 50-round magazine was dropped also. A 20-round magazine was considered to be the largest needed for semi-automatic fire.

Firing Demonstration Held

A general firing demonstration for rifles that survived the preliminary trials was held at Aberdeen Proving Ground June 16, 1941. During a meeting of the Ordnance Subcommittee that afternoon, the Harrington & Richardson (Reining), Woodhull, and Savage rifles were rejected from further consideration in their present forms. (With the exception of the Savage rifle, modified versions of the other arms were submitted for later tests, but all were rejected eventually.)

It was the opinion of the Subcommittee that the Springfield Armory (Garand) and Bendix Aviation Corp. (Hyde) rifles offered the greatest promise for future development. The Subcommittee recommended certain design changes in both rifles. At the request of the Infantry representative, Springfield Armory was directed to manufacture five rifles with bottom magazine feed, and the Bendix Aviation Corp. to manufacture five rifles with conventional stock form without a separate pistol grip.

These changes resulted in a second Springfield rifle heavier than the first model and lacking some of the original design advantages, and a second Bendix rifle having an inconveniently long receiver. In particular, though the second Springfield rifle still turned out better than any other tested at that time, it was not the equal of the first Springfield entry. Had it not been for the extraordinary good fortune of the later last-minute Winchester entry, this would have required the adoption of a rifle which was not the best available. Situations like this result from a using service specifying not only what an item must do, but how it must be designed.

It was directed that one rifle of each type be fitted with a muzzle brake and that five 10-round and five 20-round magazines be supplied for every rifle. The request for muzzle brake-equipped rifles evidenced renewed interest in a rifle capable of full-automatic fire.

Harrington & Richardson on its own initiative had the designer alter its rifle to gas operation, with as few other changes as possible, and resubmitted the rifle in that form.

The service tests of the modified rifles were scheduled to begin Sept. 15, 1941, at Aberdeen Proving Ground, conducted by Infantry personnel and witnessed by representatives from the other Arms.

In the interim, an all-metal, gas-operated rifle possessing considerable merit was presented for examination by R.J. Turner. The Turner rifle weighed 4.2 lbs., less sling and magazine. It was of highly unusual design, with the gas cylinder on the right side of the barrel and a very short and compact action of about the dimensions and appearance of a medium-size padlock. (Some of the Proving Ground personnel jokingly asked Turner whether he was a padlock designer.) These features made the rifle very short, handy and light. However, its late appearance gave the designer little time to refine the functioning. The rifle was given the preliminary tests Aug. 18-20, 1941. These revealed certain minor faults, but the inventor was advised that he could resubmit the rifle for further trial if the deficiencies were corrected.

The Chief of Infantry recommended that no rifle having the gas cylinder on top or at the side be considered for adoption unless it was unavoidable.

Winchester Entry

On Aug. 8, 1941, Edwin Pugsley of the Winchester Repeating Arms Co., submitted a light rifle for consideration by the Subcommittee. This gas-operated rifle utilized the tappet or short-stroke piston principle invented by David Marshall Williams to unlock the bolt, which was conspicuously like the bolt of the M1 rifle. The model rifle weighed slightly less than 5 lbs., including its six-round vertical-column box magazine and sling. It was not a true pilot model since it had many parts assembled by welding and brazing; it was essentially a mock-up to show the general pattern and action design. The Subcommittee was so impressed with this rifle that it was decided to send it to Aberdeen Proving Ground for limited firing tests. Winchester was encouraged by the Subcommittee to produce from one to five rifles for the forthcoming tests.

At the time of the first light rifle trials, Winchester was deeply involved in the manufacture of the M1 service rifle under an educational contract order and was unable to enter an arm in the trials. However, Winchester engineers had accumulated a valuable background of experience in the military rifle field. In 1940 they had developed a successful prototype rifle which had proved the soundness of the Williams short-stroke piston principle.

Winchester engineers required only 13 days to assemble the model arm submitted to the Subcommittee by Pugsley. Following successful completion of its initial firing tests, Winchester had little more than a month to produce a second model for the final service tests. The fact that it did so was a remarkable achievement.

The second Winchester rifle did not arrive at Aberdeen Proving Ground until the afternoon of Sept. 14, 1941. Preliminary testing of this rifle was begun immediately and was completed without difficulty by 6 p.m. During a 1000-round functioning test, the Winchester rifle had only four stoppages.

Rifles declared eligible for the Service trials were the Hyde-Bendix, Springfield bottom-feed, H&R-Reising gas-operated, Turner, and the Winchester. The Auto-Ordnance Corp. rifle had been withdrawn previously by its manufacturer.

The Service test program extended over seven days and was indicative of the rigorous tests which prospective U.S. military arms must undergo and pass before adoption. Testing was conducted by personnel from the Office of the Chief of Infantry and the Infantry School. The officer in charge was Lt. Col. Walter G. Layman, Inf. The seven-day test program involved the firing of many thousands of rounds from each rifle to determine both accuracy and functional reliability. Among the details covered by the test program were disassembly and reassembly procedures, effective rates of fire, cleaning and preservative materials needed, and ability of the rifles to function when exposed to dust, dirt, mud, and rain. Other tests investigated performance capabilities of the rifles when heated from firing and when fired without lubrication. Methods of carrying the rifles and ease of getting them into action were studied also.

Three days after the trials had begun, the field of contention had been narrowed down to only two competitors, the second Springfield Armory rifle and the Winchester. The Winchester rifle was chosen unanimously by the Test Board. It was unquestionably the right decision. In transmitting the test report to the Chief of Ordnance, the Chief of Infantry wrote as follows:

September 29, 1941

Subject: Test Report of Light Rifle, Caliber .30

To: Chief of Ordnance

- Enclosed herewith is Report of Service Test of Light Rifle, Caliber .30, in duplicate, as conducted by a Test Board appointed by the Chief of Infantry in accordance with letter Chief of Ordnance, Subject: "Light Weight Rifle", dated June 4, 1941. This report consists of an original Service Test Report, Volumes I and II, and a Supplementary Service Test Report, Volume III.

- The Chief of Infantry concurs in the recommendation of the. Test Board, that the Winchester rifle with minor modification, be adopted as the standard light rifle for use in the military service.

- The Chief of Infantry further recommends that the following modifications of the subject rifle be made.

-

Addition of a knurled buttplate.

-

Stock to approximate the dimensions at drop of comb and heel and length of pull of the Rifle, Caliber .30, M1, except smaller in size. Other stock dimensions on subject rifle are satisfactory.

-

Strengthen forearm walls to increase rigidity.

-

Change direction of ejection to right front.

-

Install a front sight similar to that on the Rifle, Caliber .30, M1.

-

Install a rear sight capable of being adjusted for ranges of 50-yd. increments from 100 to 300 yds. inclusive, sight picture size same as on test model. The rear sight to be adjustable for three points of right and left deflection.

-

That a 15-round clip be adopted as standard. Such clip to be constructed to be as near rust-free as possible. The basis of issue to be six clips per rifle.

-

- The Chief of Infantry considers that the new light rifle will be utilized by nearly all branches of the service. The best manner of carrying the weapon will depend to a great extent on the primary duties of the personnel carrying the weapon. Therefore, it is recommended that the method of carrying the rifle and ammunition be submitted to a joint board composed of representatives of all the using arms and services for study and recommendation of the earliest practicable date.

- The Chief of Infantry is now engaged in further studies as to proper means of carrying both ammunition and rifle by infantrymen. Recommendations concerning this point will be made subject of a separate communication.

Courtney H. Hodges

Major General Chief of Infantry

In view of the above recommendation by the Chief of Infantry, the Ordnance Subcommittee recommended as follows:

- "a. That the caliber .30 light rifle submitted by the Winchester Repeating Arms Company, modified substantially in accordance with the recommendations of the Chief of Infantry as recorded herein, be adopted as a standard article. In the event it is impossible to procure a rear sight which meets the above characteristics; the rocker type sight similar to the one on the model will be acceptable until the desired sight is tested and approved.

- That the weapon discussed herein and recommended for adoption as indicated in sub-paragraph a above shall have the nomenclature as follows: Carbine, Caliber .30, M1."

Acting upon the recommendation of the Ordnance Subcommittee, the M1 carbine was approved for adoption and standardization by the Secretary of War and the Adjutant General Oct. 22, 1941.

A production priority of "Essential—Three Stars" was given the new arm and its procurement was contemplated from commercial sources. The estimated unit cost in quantity production was $50 which included essential spare parts.

On Sept. 30, 1941, the Ordnance Committee had approved the standardization of the Cartridge, Caliber .30, Short Rifle, M1, and assigned it the nomenclature Cartridge, Carbine, Caliber .30, M1. It will be recalled that DuPont IMR 4227 had been the propellant specified originally for use in this cartridge, but this powder had proved too bulky to give the required velocity and Hercules 2400 powder gave excessive muzzle flash.

Accordingly, all but 50,000 rounds of the original 250,000-round lot were loaded by Winchester with DuPont EX-4809 powder. The odd 50,000 rounds were loaded with Hercules 2400 powder. The charge of DuPont EX-4809 powder gave an instrumental velocity of about 1,800 f.p.s. at 53 ft. from the muzzle. Because of difficulty with the 31,000 p.s.i. pressure level, the pressure level for the cartridge was raised to 38,000 p.s.i. and later to 40,000 p.s.i. The instrumental velocity was increased to 1,900 f.p.s. at 53 ft. from the muzzle, with an average chamber pressure not exceeding 40,000 p.s.i. The above instrumental velocity was equivalent to a muzzle velocity of 1,970 f.p.s. Hercules 3950.8B powder was approved as an alternate propellant for the M1 carbine cartridge.

During World War II, the M1 carbine ball cartridge was manufactured by the Western Cartridge Co., Winchester Repeating Arms Co., Remington Arms Co., Lake City Ordnance Plant, and by the Kings Mills Ordnance Plant. The commercial firms involved were allowed to use their own noncorrosive priming mixtures.

The original bullet used in loading the ball cartridge was of cup-base type with nominal weight of 108 grs. It was manufactured up to Feb. 14, 1942, when it was superseded by a flat-base bullet with nominal weight of 111 grs. The original cup-base bullet tended to upset in firing, leaving a ring of gilding metal in the front end of the chamber. Adoption of the flat-base bullet eliminated this problem. (The designation Cartridge, Ball, Carbine, Caliber .30, M1 was assigned on Sept. 14, 1944, to differentiate that round from the tracer and grenade launching cartridges that had been developed later.)