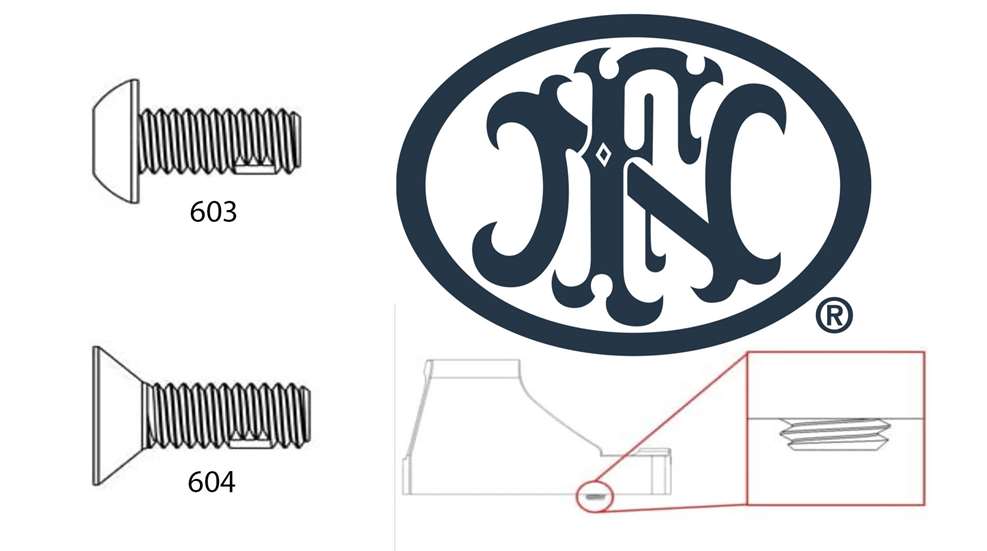

FN America recently discovered a condition on the FN Reflex MRD pistol that, in very limited circumstances when using the incorrect set of screws to mount specific optics, the pistol could experience binding, cycling issues or interference with the firing pin safety block. The condition was first identified on a Reflex MRD with a Viridian RFX11 optic installed using the incorrect FN-provided screws, which were labeled “604.” They were too long. In this case, the screws labeled “603” should have been used.

The company is reminding owners that when mounting any optic to the Reflex MRD, it is imperative to use the correct FN-supplied screws and only the correct FN-supplied screw. Do not use screws provided by the optics manufacturer. Those were not designed to interface specifically with the Reflex MRD and could cause damage to the slide.

The chart in the Reflex Owner’s Manual explains which size screw to use. It has been updated to include the Viridian RFX11 Optic. When installing the Viridian RFX11 optic, make sure to use only the FN-provided “603” screws to ensure proper function of the pistol Screw No. 603 is at the top in the illustration above, with 604 below. Before installing all other optics, refer to the chart in the owner’s manual for the correct-sized screws.

The FN Reflex Owner’s Manual or Optics Mounting Guide is available online here. If your optic is not listed, please contact FN Customer Service by e-mail or by phoning (800) 635-1321. The department is open from 8 a.m. to 5 p.m., Eastern time, Monday through Friday.

To ensure correct FN-supplied screws are being used you can double check with the following procedure. Hold the optic separately from the pistol, place the screws through the screw holes in the optic and measure or count the threads protruding from the bottom. They should measure no more than .045", or three threads visible (figure to the right, above).

The screws should also be installed to the correct torque setting, which is 6 to 8 inch-pounds, regardless of what is recommended by the optic manufacturer. Take care not to overtighten beyond the correct torque settings. Doing so may deform or compress the optic housing.