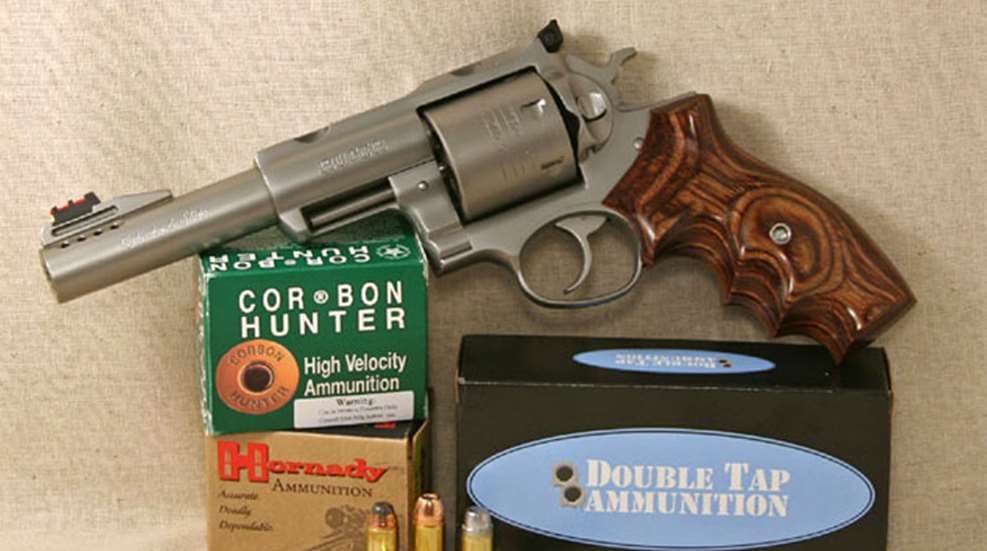

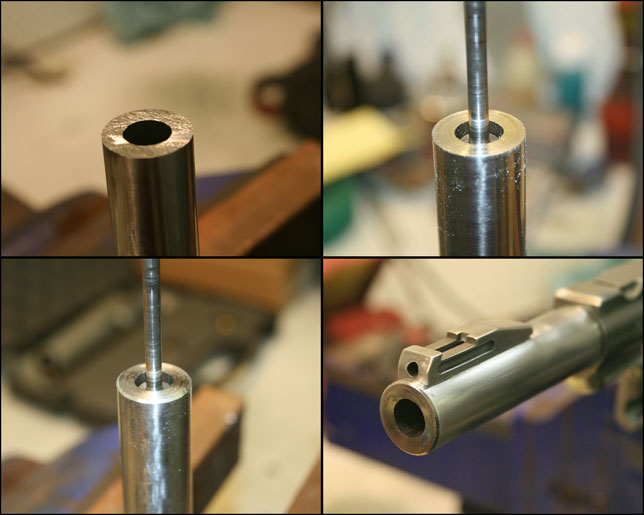

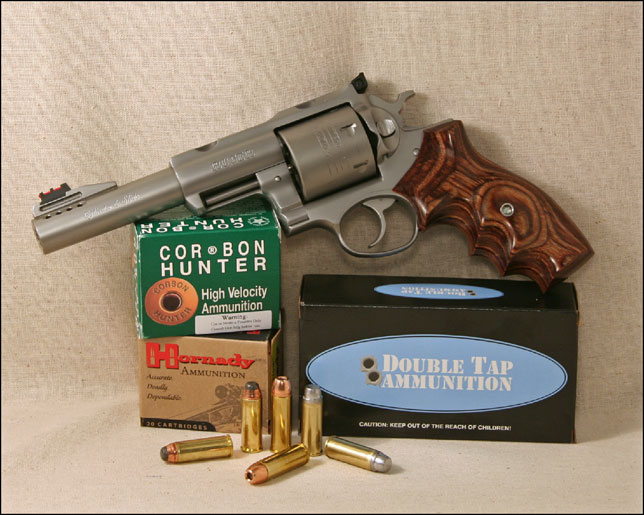

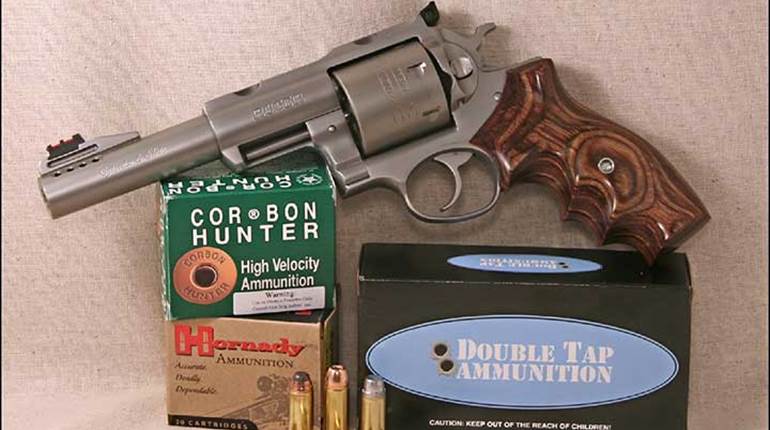

Customizing the Ruger Super Redhawk

Interests

Gun Of The Week: Rock River Arms LAR-22 Tactical Carbine | An Official Journal Of The NRA

- NRA Hunters' Leadership Forum | A Legacy of Passion and Generosity: The Shea Family’s Commitment to the NRA

- The Armed Citizen® July 11, 2025 | An Official Journal Of The NRA

- NRA Hunters' Leadership Forum | At Long Last: Pennsylvania Governor Signs Historic Bi-Partisan Legislation Overturning State’s Sunday Hunting Ban