Long before Samuel Colt, Sharps Rifle Manufacturing Company, and Winchester Repeating Arms Company came on the scene, earlier American gunmakers carved out a foothold and laid the groundwork for them. Counted among that number of pioneer gun makers were John H. Hall, Simeon North and Eli Whitney. Each secured their own niche within the early American firearms manufacturing industry.

On the very day of his 16th birthday on July 13, 1781, a patriotic Simeon North thought to himself, “What better way to mark such a pivotal milestone than to enlist in the Continental Army?” He was denied. The reason? Possibly his young age. Failing to secure a place in America’s young army was most likely a disappointment to the young man, but it was a godsend to the embryonic United States. Over the years, Simeon North would transform from a farmer to a manufacturer of scythes, and in 1799, he secured a contract from the U.S. War Department for 500 pistols. More contracts would follow.

Simeon North portrait.

Simeon North portrait.

By the time the War of 1812 was on the horizon, Simeon North was a full-time gun manufacturer. A year into the war, the U.S. government awarded him a contract for 20,000 pistols. This new order would require more infrastructure than North could provide at the present time. His solution: Buy acreage in Middletown, Conn., and harness waterpower from the Coginchaug River to operate his new gun manufactory. The total cost of his new undertaking was enormous in its day—$100,000. This included the new brick structure with the latest machinery to turn out guns. That was a heady sum. That same project today would cost in the millions.

Gaining a large arms contract was important in its own right, but the stipulation proposed by North and etched into the contract was the following: “The component parts of pistols are to correspond so exactly that any limb or part of one pistol may be fitted to any other pistol of the twenty thousand.” This government contract was the first of its kind, wherein a manufacturer agreed to turn out 20,000 pistols all with identical, interchangeable parts. According to North, “he attempted to complete only the first few hundred pistols to the specification of uniformity, however … because the War Department made changes in the model.”

North’s new factory on the banks of the larger Coginchaug River (then called the "West River") in nearby Middletown, Conn. Image courtesy of tincanbandit.blogspot.com.

North’s new factory on the banks of the larger Coginchaug River (then called the "West River") in nearby Middletown, Conn. Image courtesy of tincanbandit.blogspot.com.

The end of the war in 1815 by no means meant the end of North’s business. He continued to turn out pistols to the tune of no less than 50,000. Over the next quarter-century, North’s gun manufactory turned out rifles in the thousands. In 1851, with age catching up to him (after all, he was now 85), he retired. With four of his five sons involved in the business, he most likely felt the business was safe in their hands. Apparently not! Simeon North passed away in 1852. North was the lifeblood of the company; without him at the helm, within one year of his death, the gun manufacturing business he had spent 50 years running was shuttered.

Working within the same time bubble as North, was John H. Hall. Living in Portland, Maine, Hall earned his living as a barrelmaker, boatbuilder and cabinetmaker before turning to manufacturing guns. John Hall would merge the machinery he had devised himself with the slower, laborious task turned out by artisans. Hall’s determinations led to expanding the American approach to firearm manufacture. Hall was driven to fabricate his patented breechloading rifle with interchangeable parts, improving on the systems used by North, as well as those of the Springfield and Harpers Ferry armories. Hall was a step ahead of North, and especially Eli Whitney, in the pursuit of completely interchangeable parts. In Whitney’s case, his lock for his muskets was interchangeable, but the parts making up the lock itself, were not. North and Whitney’s efforts were somewhat lessened in the face of economic pressures, as all their funding was via the U.S. government, which while professing to champion interchangeable parts, still held to the notion of artisan experience over machine-made. Hall was not tied down by the same financial constraints, as he used some of his own money to pursue his own vision.

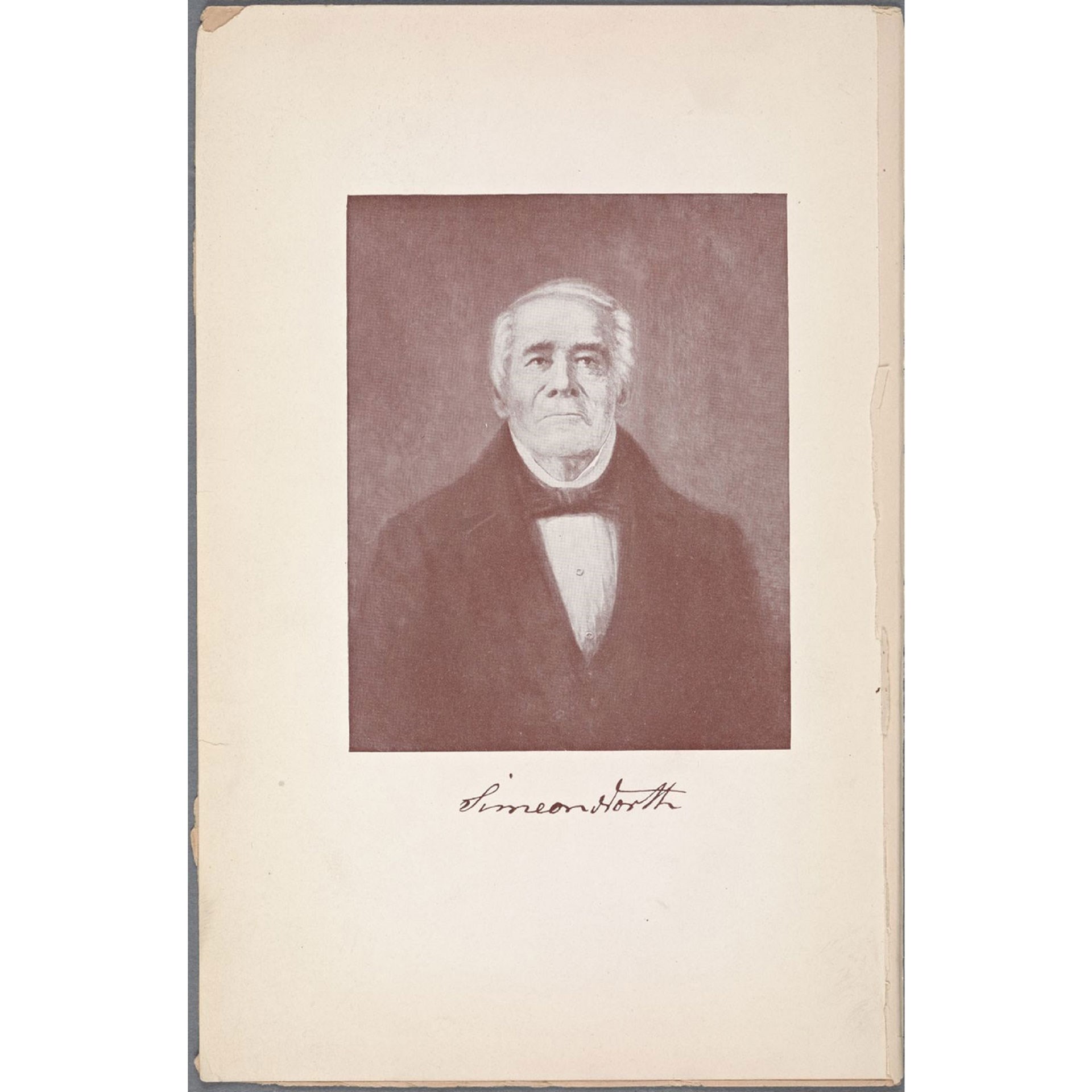

Shown above is a photo of a contemporary drawing of the 1819 Hall Rifle with its breech open.

Shown above is a photo of a contemporary drawing of the 1819 Hall Rifle with its breech open.

In 1811, Hall applied for a patent for his breechloading rifle, but the Commissioner of Patents William Thornton stated he had conceived of that same rifle. Hall had no choice but to file the patent jointly with Thornton. But Hall took his own route with the patent, turning out eight breechloaders for the War Dept. After the eight guns passed muster, the U.S. military in 1814, offered Hall a contract for 200 rifles. Not having the infrastructure set up to fulfill the order, Hall had no choice but to turn down the contract. But the following year, Hall professed he could deliver any amount of the rifles the War Dept. contracted for. Hall made a number of proposals for a high volume of guns, between 500 and 1,000. The head of the U.S. Ordinance Dept thought the prices proposed were too high. It was finally settled on 100 breechloaders—Hall turned over 100 in November 1817.

Hall had something North and Whitney did not possess; an intellectual thought process that produced the tools to machine parts to meet more precise standards. This really paid off. In testing his breechloader versus muzzleloaders, Hall's won, hands down, due to its ease in loading versus that of the muzzleloader. The price per unit was still too high, but a contract viewed as agreeable to both parties was hammered out. In April 1820, Hall, at his Rifle Works located at Harpers Ferry, began work on 1,000 breechloaders. It would take until December 1824 to complete the order for the U. S. government. For his efforts, Hall was paid the agreed amount of $60 per month and $1 per gun, which totaled in the neighborhood of $3,400. To cap this all off, each gun was a duplicate of one another—firearms with 100 percent interchangeable parts. This was due to the development of several machine tools, fixtures and gauges he created on his own. Hall proceeded to employ more machinists rather than gunsmiths. His greatest contribution to gun manufacturing was proving that machining could turn out a superior product in a shorter time than in an artisan’s hands alone. As a result, the Springfield Armory incorporated much of Hall’s approach into its own armory system. In 1832, Col. George Talcott of the Ordnance Dept. touted the reasons for Hall's success, stating Hall’s "manufactory has been carried to a greater degree of perfection, as regards the quality of work and uniformity of parts than is to be found anywhere – almost everything is performed by machinery, leaving very little dependent on manual labor."

This extremely rare Model 1817 U.S. contract breechloading flintlock rifle is from John H. Hall's first government contract for 100 firearms, which were sent to Fort Bellefontaine. Fewer than five examples are known to exist. Image courtesy of the Missouri History Museum.

This extremely rare Model 1817 U.S. contract breechloading flintlock rifle is from John H. Hall's first government contract for 100 firearms, which were sent to Fort Bellefontaine. Fewer than five examples are known to exist. Image courtesy of the Missouri History Museum.

These early American gun manufacturers were men of many firsts. Eli Whitney’s contract in the amount of $134,000 for 10,000 muskets, was issued on Jan. 14, 1798. But at the time he put his pen to that document, he had not the financial means nor the physical infrastructure to complete the contract. More importantly, he possessed no experience whatsoever in making firearms. That contract was the first of its kind, wherein a private party was given an advance by the U.S. government for work not yet completed. This stipulation that Whitney would receive $5,000 upfront was written into the contract.

Whitney’s foray into the world of gunmaking came by way of a different route than either Hall or North. Whitney had invented the cotton gin, but financially, it proved a disaster. He incurred heavy debt in defending his patent claim and attempting to manufacture the cotton gin—it proved a nightmare. He turned to gun manufacturing as a last resort to keep himself from bankruptcy. A government contract for 10,000 muskets was a tall order when time was of the essence, but Whitney looked to machinery needed in crafting the high volume of muskets, run by waterpower, as opposed to craftsmen making one gun at a time. But all this aside, working from New Haven Whitney did not complete the contract until 1809. Whitney lacked the technical expertise of both Hall and North.

Portrait of Eli Whitney (1765-1825) by Samuel Finley Breese Morse, c. 1795.

Portrait of Eli Whitney (1765-1825) by Samuel Finley Breese Morse, c. 1795.

Salesmanship proved his niche; without it, there would have been no Eli Whitney, gun manufacturer. It required quite a bit of self-promotion and access to the right people to be allowed to drag out a contract for 11 years. According to David A. Hounshell’s work, From the American System to Mass Production, 1800-1932: The Development of Manufacturing Technology in the United States, although touting the principles in interchangeable parts, Whitney’s muskets were fashioned without them. But firearms needed for the War of 1812 pulled Whitney from the financial fires for a second time. With the onset of that war, another U.S. government contract came Whitney’s way. This order was for 15,000 muskets. The U.S. government was not his only benefactor. The state of New York contracted him for another 15,000 firearms. Whitney was now reaping the financial rewards, but it wasn’t from his cotton gin. Had it not been for the war, it’s highly likely that he would not have been awarded another federal contract, due to his poor performance in completing the 1798 contract.

As these early gun manufacturers faded away, the new cadre of gunmakers came to the fore. The new patent arms makers of Colt’s revolvers and the Sharps rifles among several others, benefited from decades of early advances in arms manufacturing.