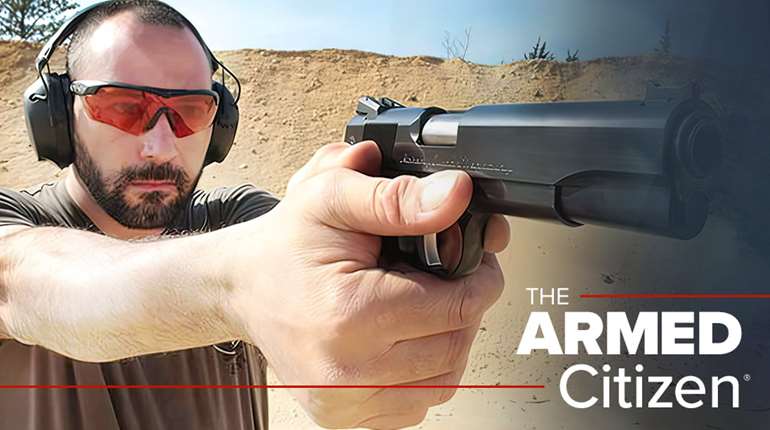

After deciding to obtain a concealed-carry permit for my self-defense handgun, I began researching handguns styles, calibers and features. I knew I wanted something compact and easy to conceal, but powerful enough to authoritatively stop a perpetrator.

I looked at both pistols and revolvers, and seriously considered a snubnose .357 Mag., but in the end decided on a semi-auto. Since I already owned a 9 mm, I decided to go with a larger caliber-a .40 S&W or .45 ACP. An acquaintance had a SIG P226 for sale with both .40 and .357 Sig barrels. The gun was a little bigger than I wanted, but I was interested in the dual calibers and would have bought it if we could have agreed on price.

Eventually, I wandered into a little hunting/gun shop in Tupelo, Miss. It was running a pretty good sale and I picked up a Kimber Ultra Carry in .45 ACP for $660, plus tax. This was one of the early models featuring a skeletonized trigger and hammer, along with diamond-checkered rubber grips and black, low-profile combat sights. At the same time, I bought some Winchester white box ammunition-because that gun was just begging to be fired-and headed to the hill in my parents’ pasture that served as my home-range backstop.

Even though it took time to get used to the recoil of the .45 chambering in such a small package, the gun was quite accurate. The trigger was light and crisp, allowing me to produce small groups at a variety of distances. It also ran fairly well with the full-metal-jacket rounds, but there were a few hiccups, namely a couple of failures to feed, during the 100-round session. I just assumed the problem was being unfamiliar with the powerful recoil of the compact handgun. It wasn’t until a few weeks later when I ran some high-grade hollow points through the gun that I started wondering if there was a problem.

With hollow-point ammunition, my Ultra Carry failed to feed once or twice per magazine. It only took a small push to get the gun back in action, but since I was planning to use it as my primary defensive handgun, I was concerned. Reliability was more important than power and concealment, so I regulated it to a cool-looking range gun and went to my Beretta 92 as my carry gun.

Over the next few months of range use, I noticed the gun started running well with FMJ ammunition. I swapped over to hollow points, and only had a problem every few magazines. It was as if the gun was beginning to realize the point of its existence. Then at around 500 rounds, it’s as if everything just clicked, and the gun started running flawlessly with all types of .45 ACP ammo. It was then that I realized that the gun merely needed a break-in period.

Reflecting on more than a decade of shooting and self-defense research, I have seen numerous high-quality 1911s require that same 400- to 500-round break-in period. The brand made little difference, as long as it was one of the popular semi-custom guns-Kimber, Smith & Wesson, Springfield. If the gun had tight tolerances, it needed breaking in. It even says so in the manual that comes with each Kimber 1911 handgun, which I didn’t read at the time of purchase.

“Kimber 1911s are built with extremely tight tolerances,” said a Kimber spokesman. “The barrel bushing and slide have to break into one another.”

The Kimber manual explains a fairly specific process that begins with cleaning and lubricating the gun before firing 100 to 150 rounds of quality FMJ ammunition at the range. Users should then clean and lube the gun again, and continue the process until running 400 to 500 rounds through the gun.

The reason for this is the tolerances between parts, which are much tighter than the M1911A1s with which so many people are familiar. The 1911s used by U.S. troops in World War I, World War II and beyond were built for reliability on a battlefield, rather than pinpoint accuracy. They were rugged, work-horse pistols built with the best practices of the time, which earned them their iconic status. However, technology has greatly improved during the past century. Today, high-end 1911 pistols are built on state-of-the-art CNC machines with tolerances in the thousandths of an inch. The new processes make for more accurate and much tighter guns coming off the factory floor. Kimber actually mates a barrel to a slide so that the pair goes through the entire process together, with over 200 inspection points along the way.

Exacerbating this issue is powerful recoil in a small package. Full-size, all-steel 1911s weigh close to 3 pounds, while aluminum-frame compacts weigh less than 2 pounds. While 10 to 12 ounces doesn’t seem like much, unless it’s riding all day on the hip, that extra weight really helps dampen felt recoil. That extra snap from a lightweight compact can even catch experienced shooters by surprise, leading to “give” in the shooting wrist, commonly known as limp-wristing, which can prevent the recoil spring from fully engaging and having the strength to bring the slide back to battery. As such, it is just as important to familiarize yourself with the pistol.

“It is important to break yourself into the gun,” said a representative from Kimber. “Users need to clean and lubricate the gun properly, and learn the gun.”

Learning the gun is crucial, as the trigger and sights on every firearm brand are different. Sure, most folks can pick up any standard firearm and perform fairly well, but a gun’s owner usually has an edge over others with his or her gun because of familiarity.

Finally, a concealed-carry handgun needs a break-in period due to the need for absolute assurance that it will fire when needed. Sure, there are pistols that will run almost any quality ammunition straight out of the box, but I would still never consider carrying a semi-auto that I hadn’t personally fired at least 300 times, and preferably more. I have to have confidence in the gun I carry.

The Kimber Ultra Carry riding my hip in a Milt Sparks Versa Max II holster on a daily basis has sent thousands of rounds downrange. I’ve fired it dirty. I’ve fired it wet. I’ve run all manners of ammunition through it, including some very dirty reloads that I thought might choke it up, but didn’t. It’s beat up and there is a slight rattle somewhere on the inside. However, it fires to point of aim every time the trigger is pressed, regardless of conditions. And that is why you break in a gun: You are trusting it with your life.