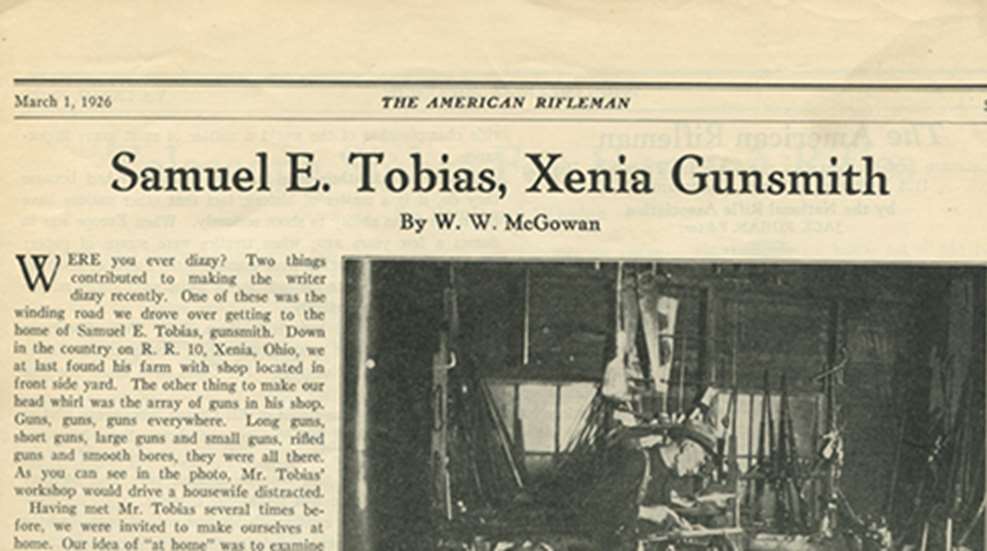

By W.W. McGowan

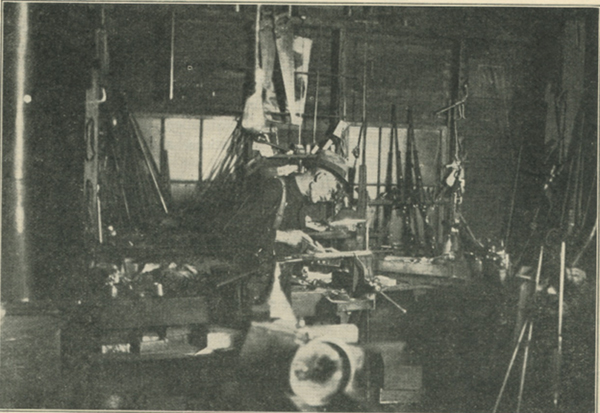

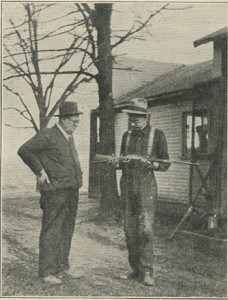

Were you ever dizzy? Two things contributed to making the writer dizzy recently. One of these was the winding road we drove over getting to the home of Samuel E. Tobias, gunsmith. Down in the country on R.R. 10, Xenia, Ohio, we at last found his farm with shop located in front side yard. The other thing to make our head whirl was the array of guns in his shop. Guns, guns, guns everywhere. Long guns, short guns, large guns and small guns, rifled guns and smooth bores, they were all there. As you can see in the photo, Mr. Tobias' workshop would drive a housewife distracted.

Having met Mr. Tobias several times before, we were invited to make ourselves at home.  Our idea of "at home" was to examine as many of the guns as possible, so we got busy. Of particular interest was the '86 Winchester which Mr. Tobias is shown working on. This was with "Teddy" on his African trip. Being an admirer of Teddy, we naturally enthused over this gun! Next to command our interest was a S.A. Colt .45. This gun was carried by a certain U.S. captain. It had notches in the grips. Mr. Tobias solemnly assured us that each notch represented the demise of a Moro chief.

Our idea of "at home" was to examine as many of the guns as possible, so we got busy. Of particular interest was the '86 Winchester which Mr. Tobias is shown working on. This was with "Teddy" on his African trip. Being an admirer of Teddy, we naturally enthused over this gun! Next to command our interest was a S.A. Colt .45. This gun was carried by a certain U.S. captain. It had notches in the grips. Mr. Tobias solemnly assured us that each notch represented the demise of a Moro chief.

To enumerate all the interesting guns in that shop would take a year. "Tobe," as he is known to his friends, says it will take longer than that to get through working on them.

Mr. Tobias, who is known wherever fine gun work is known, is a fairly good looking chap 61 years young. He is the father of six children, four of them boys. None of the boys follow gun-craft. Mr. Tobias was born within one-half mile of his present home. He has always been a gun "nut." When four years old he whittled out a wooden pistol with his dad's knife. Next came a wooden crossbow. He didn't say whether or not he used the same knife. Next was a long bow with which he bumped off woodpeckers. His first gun was an old English Tower musket with which he killed 43 rabbits the first year. (Caught them on the nest, we think.)

In 1882 he made his first stock for sale. Then he worked on muzzle-loaders, resighting, dressing up the muzzle, etc. Next he made new muzzle-loaders, and then started reboring .22 rifles into .25 caliber.

"Tobe" is the man who "put the tube in the rifle" way back in 1900. Here's how it all came about. C.T. Harner, "the gunstock man," asked Sam one day why he could not bore out a barrel and put in a tube, then rifle the tube! Sam said it could be done and C.T. said he would get him all the work he could handle, and to quiet Sam he sure started something!" His first job went to a man in Columbia, South Carolina. The first pistol he made for sale was a muzzle-loader. This gun is still owned by Mr. Keenan of the Manhattan Gun Club, New York City, who wrote in five years ago wanting some more made.

One gun which caught our eye, and we are truly glad it did not catch us anywhere else, weighs 23 pounds! It is a .38-55 with hex barrel. Has all the trimmings which went with the old style target rifle of that day. Even has a cross shelf at the muzzle to secure perfectly plumb front sight, and we think maybe also to help hold up about 17 of that 23 pounds.

Now, fellows, here comes the best part of the whole story--Ford parts make the best repair parts for your guns! (Page Henry.) The writer, who earns his daily beans selling Fords, thinks Tobe handed out that last just to make us feel good, but were assured that while they were harder to work, they made the best parts. He has never had a repair part taken from Lizzie's anatomy come back as defective. How's that? Old Ford axles make real pistol barrels, too--all you have to do is drill, rifle, fit action, sights, grips, etc., and there you are! Step on the gas, boys, we're off!

Now, here is something worth remembering. After some persuasion and soft soap on our part we got Tobe to tell us how he finishes a stock.

First, follow directions in "Amateur Gunsmithing" ($1.50 to members of the N.R.A.), relative to sanding down. He stressed the point of forced drying between sandings.

Should be dried out over a hot fire or stove as quickly as possible without burning the stock. Then, when through drying, when the stock will remain perfectly smooth after wetting and forced drying, fill with a filler of corn starch and powdered pumice stone, equal parts, mixed with Japan and turpentine. Let this dry hard, then sand down smooth. This will fill all the pores of the wood. Then oil with boiled linseed to which has been added 20% turpentine. Rub each application in thoroughly with the hand. For best results this should be done every day, using little oil, and lots of rubbing. Directions say to rub as above for three months--suit yourself. Then do your checking, not before. Use little oil to finish off, checking if you object to the finish it then has.