Colt’s landmark factory in Hartford, referred to as the Colt Armory, was called “the greatest individual enterprise ever attempted in this country” when it opened in 1855. Heated by steam and lit by gas lamps, the factory was topped by a sapphire blue-onion dome in the style of the Byzantine churches Sam Colt had seen in Russia. Atop the dome pranced a gold-plated rampant Colt holding a broken spear, Colt’s distinctive trademark that continues to this day.

I recently visited Colt'snewest factory in West Hartford, asthe Armory has long since been taken over by boutique shops and much-too-healthy sandwich shops. I walked through a maze of ultra-sophisticated CNC machining centers, polished robots amid oily, dirty, belt-driven machines that date back to 1911. It waslike standing with one foot in the Information Age and the other in the Industrial Revolution.

I paid particular attention to how Colt makes the M1911 Government Model, referred to here as the Model O.

I marveled at the juxtaposition of the centuries as CNC operators punched LCD computer screens while highly skilled polishers applied a mirror sheen to a slide destined for the tuxedo of gun finishes, Colt Royal Blue. One is the result of a college course in CNC operation, the other a delicate touch acquired over more than a decade of apprenticeship.

The average years of service of a craftsman in Colt’s Polishing Department is 30. I suspect the average age, period, of a CNC technician is about the same. Yet it takes both skill sets, the modern and the traditional, to make a Colt Model O.

I’ve toured other gun companies that manufacture M1911s and I can assure you that no one else builds a Government Model the way Colt does. Take the frame, for example. It starts as a forging which is not unusual—many makers begin with forgings. However, while others get the forging into a CNC as soon as possible, Colt begins a lengthy process of preparing a frame with vintage machinery that dates to the origin of the 1911.

The frame is surface ground and then the first of three holes are drilled into the grip. Holes are drilled (I won’t say which ones) which will serve as locating holes for all subsequent operations as the frame progresses from machine to machine.

The trigger bow recesses are broached, not machined. The mag well is broached as well. It takes a broach over three feet long to pull through the mag well. The broach’s alignment is done by hand, by a trained craftsman.

Eventually the frame makes it into a CNC where further cuts are made and holes are drilled, but no cutter marks remain. It’s off to the Polishing Department where it’s sanded and buffed by arguably the most talented worker in the entire factory, save Colt’s master engravers.

Slides are made in the same way, a blend of old and new. I toured HK’s U.S. factory once and an engineer proudly told me that once an HK forging is inserted into a “coffin” fixture in a CNC machine as long as a cafeteria table, it comes out finished. “No secondary operations at all,” he said proudly. “Finished part, ready to go to assembly.”

Not so at Colt. The slide is broached, ground, honed and cut—the locking lugs and breech face require the very best of the oldest machines. And then it’s off to the Polishing Department where everything is done by eye and hand.

While various M1911 manufacturers are quick to brag about their very latest in metal injection molding (MIM) and how much money it saves, my Colt tour guide, Mike Guerra, looks at the floor sheepishly when I ask him how many parts are MIM. “One,” he admits embarrassingly, like 10-year-old caught stealing a lollypop. “The disconnector.”

“Everything else is machined from either a forging or bar stock,” Mike adds hastily. “Or aluminum, if it’s a Lightweight Commander.”

When I get to final assembly, I meet Lewis P. DeLuca who is putting together a Model O with a fluidity and smoothness that comes only with habit. I ask how many years of service he has and, looking up to regard me but continuing with his assembly, he replies, “Forty-eight.”

I wear hearing aids, a result of too much IPSC and too many .375s in Africa, so I think I’ve misheard him. “I beg your pardon, sir? How many did you say?”

“Forty-eight,” DeLuca repeated, smiling. “You have a hard time hearing too?”

“Sure do.”

“Know what you mean.”

“That’s absolutely amazing… you’ve been assembling the Model O for half of its life!”

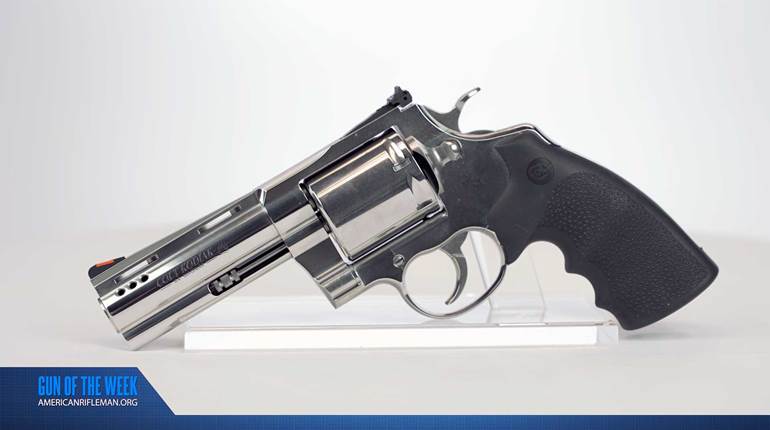

“Well, not just the Model O. I’ve worked all over the factory. I’ve assembled Model Ps, Pythons, all of them.”

“Which is the hardest?”

“They’re all about the same, once you figure them out.”

“How many Model Os do you think you’ve assembled?”

Lewis chuckles, a deep belly laugh. “No way of knowing that. A lot!”

I thank Lewis for his time and apologize for the interruption except I see that it really wasn’t much of an interruption as he finshed the slide while we were talking. I move on to another area of the factory, but I can’t help thinking about Lewis and the greasy, old broaching machine and the rotors in the ceiling where the old fan belts used to run—next to an $800,000 CNC machine.

Colt uses a tag line in its marketing—Quality Makes It A Colt™—but I wonder if a more appropriate one might be Experience Makes It A Colt.