On Oct. 3, 1526, the Republic of Venice sent what amounts to a purchase order to Master Bartolomeo Beretta for the manufacture of 185 arquebus barrels. That document essentially serves as the birth certificate for Fabbrica d’Armi Pietro Beretta S.p.A.—the firm today more simply known as Beretta. The Beretta family was already a known quantity in northern Italy even then, which makes firearm-related business prior to that date likely; however, floods, fires and wars during the intervening centuries have erased all earlier documentation.

With roots reaching back into the early Renaissance, the Berettas of Italy’s Gardone Valley have been in the continuous business of firearm manufacturing ever since, a heritage that positions the company as the singular patriarch of the gun world and even places it among the most enduring firms within the entire annals of human industry. Its doors first opening at a time when the notion of handheld firearms was still in its infancy, Beretta’s offerings through the centuries read like the CliffsNotes version of the history of gun development; the company has made it all. First came the matchlock- and wheellock-operated firearms, with flintlocks, percussion guns and breechloaders being added as the technology progressed.

Today, 16 generations of family ownership later, the gunmaker’s catalog features everything from highly embellished sporting shotguns to rimfire pistols. In the beginning, though, Beretta was in the business of making military arms—and in 491 years the company has never abandoned that aspect of its identity. The manufacturer’s first semi-automatic pistol design—the Modello 1915, chambered for the erstwhile 9 mm Glisenti cartridge—was adopted by the Italian military for use during World War I, and Beretta’s handguns have achieved great martial success since that time. Many other examples exist, but this is best evidenced by the 1985 selection of the Model 92 SB-F to replace the venerable Colt Model 1911 as the standard-issue sidearm of the U.S. Army (and countless other militaries and law enforcement agencies across the globe).

So in 2015, when the Army announced the XM17 Modular Handgun System (MHS) program to select a pistol to succeed the Model 92 (renamed the U.S. M9 upon adoption) and requested submittals for the associated trials, it came as absolutely no surprise that Beretta was among the companies to throw their hats into the ring for the contract. The firm even released the M9A3 (an upgraded, more modular variant of its contract gun) shortly thereafter in an attempt to derail the XM17 process entirely, an effort that was quickly rejected by military brass. Beretta’s entrant into the MHS competition, the APX (for Adaptable Pistol X—with “X” standing for multi-caliber) represents a marked departure for Beretta, as it is both the manufacturer’s first full-size, striker-fired pistol and its first full-size handgun to utilize a removable stainless steel chassis that serves as the firearm’s serialized component. And with the Army’s announcement in January that SIG Sauer’s P320 had ultimately been chosen to replace the M9, Beretta is now turning its attention toward the law enforcement and commercial home-defense markets.

According to the manufacturer, while initial development of the APX predates the XM17 competition, the handgun was nonetheless conceived from the outset to be a duty pistol for professional users. As such, the company made the wise decision from the start to involve its target audience in the gun’s development. At numerous points along the APX’s four-year design process, Beretta sought input from several hundred military operators and SWAT personnel regarding the qualities they needed and wanted most from a sidearm upon which their lives would potentially depend. Feedback from these consultants emphasized reliability, durability, ergonomics, modularity, ease of use and an optimized duty trigger. Armed with that information, Beretta’s engineers set themselves to the task of delivering the ultimate gunfighter’s pistol. The end result is a semi-automatic that Tactical Product Manager John Tamborino called “the most tested Beretta pistol yet”—quite a statement given the firm’s august pedigree.

The Italian-made APX was a blank-sheet gun for Beretta, borrowing no components or inspirations from any of the manufacturer’s extant handgun lines. A polymer-frame semi-automatic utilizing a locked-breech operating system, the barrel and slide of the APX are locked together at the moment of discharge. As both components are forced rearward under recoil, the barrel cam acts on the barrel disconnector, forcing the barrel to disengage from the slide. The slide then continues rearward as the barrel’s chamber is tilted downward out of the way, and the empty case is extracted and ejected. A captive recoil spring then forces the slide forward again, stripping a fresh round from the magazine and chambering it prior to returning to battery.

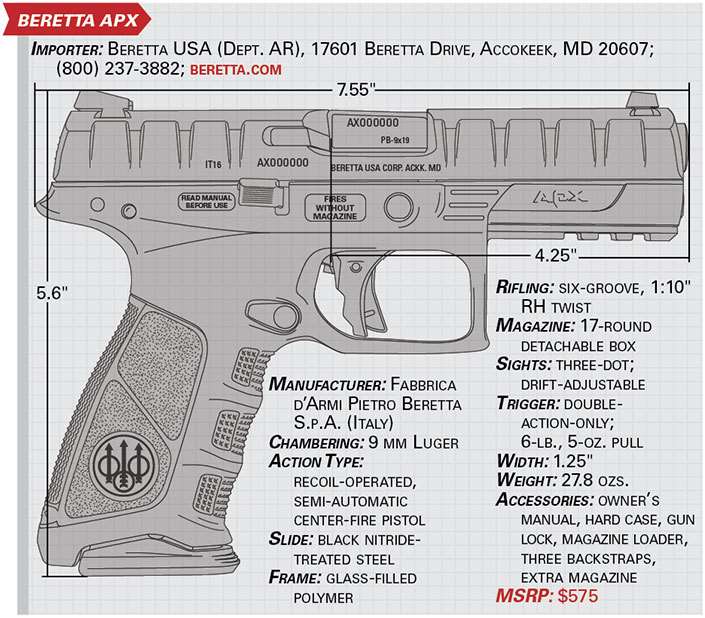

Measuring 7.55" long and 5.6" tall with a 4.25" barrel, and tipping the scales at 27.8 ozs. with an empty steel, double-stack, detachable-box magazine, four SKUs of the APX will be available at launch. Two are full-capacity models, one chambered in 9 mm Luger and one in .40 S&W, shipping with 17- and 15-round magazines, respectively. The other two are state-compliant models, chambered for the same cartridges, but instead including neutered 10-round magazines for those areas that necessitate them. Two APXs were used during the course of this evaluation, both of which were full-capacity 9 mms.

Prior to the APX, Beretta had favored the combination of a hammer-operated ignition system paired with a double-action/single-action trigger for its full-size, center-fire handgun designs (with either a manual safety or a decocker), as seen in its Model 92, 96 and Px4 series guns. However, as the popularity of that combination has waned in recent years in favor of striker-fired guns, Beretta made the decision to follow the prevailing trend. The APX’s trigger is double-action-only, wherein the trigger pull first completes the cocking of the striker before releasing it to impact the chambered round’s primer.

Citing its own research and the insights gleaned from the project’s consulting operators, Beretta tuned the APX’s trigger to break at approximately 6 lbs. of pressure—light enough to allow accurate fire to be brought to bear on the target, but heavy enough to forestall inadvertent discharge while in an adrenalized state. The trigger was designed with an intentionally wide and flat face in order to promote a straight, rearward trigger pull on the part of the user. While there is no manual safety present on the new Beretta, the gun does feature a striker block safety and a blade-in-trigger safety to help prevent accidental discharge of the pistol. Befitting of a fighting gun, the APX does not make use of a magazine disconnect safety, and will thus still be able to fire without a magazine fully seated within its well.

The APX utilizes a serialized, removable steel chassis very similar in function to the modules used by SIG’s P250 and P320 lines. On the Beretta, this structure houses the gun’s firing mechanism, trigger, ejector, bilateral slide releases and the full-length rails upon which the slide travels. The modular nature of the chassis allows it to be removed (although not a particularly simple process) for maintenance or to be installed within alternate grip frame housings in case of damage to the frame or even simply for the sake of customization—and Beretta offers aftermarket housings in Olive Drab Green, Flat Dark Earth and Wolf Grey for just this purpose. The initial APX series may only field the two full-size pistols, but given the capability of the chassis to be used interchangeably with either a 9 mm Luger or .40 S&W slide/barrel assembly, the potential exists for Beretta to further follow SIG’s lead and develop a full suite of differently sized, multi-chambering grip frame housings to fully take advantage of this flexibility. Here’s hoping that it does.

The APX’s slide and barrel are both made of a high-strength steel alloy and have undergone a black nitride treatment that diffuses carbon and nitrogen into the surface of ferrous metals, increasing their fatigue strength, lubricity, and wear- and corrosion-resistance. Sights on the APX follow the modern three-dot pattern, and a slightly enlarged front dot results in a sight picture that appears to feature three identically sized elements, which should translate into more intuitive aiming and faster target acquisition. The dovetailed, drift-adjustable inserts provide a relatively long 6.25" sight radius. A standard feature on most fighting handguns these days is a rear sight with a flat enough front surface in order to facilitate one-handed charging of the pistol against a sturdy surface like a countertop or a gun belt, and this feature has likewise been incorporated into the APX.

The most visually distinct aspect of the APX is its unconventionally broad slide serrations, which run the entire length of the gun’s top end. The aesthetics of these finger-width ribs will no doubt be polarizing, but they are unquestionably functional. Not only do they allow easy racking of the slide at any point along its 7" span, but they are even deep enough to allow one-handed manipulation of the slide—in the aforementioned manner as with the rear sight—should a tactical situation arise that requires it. I can think of no other handguns on the market today with cocking serrations substantial enough to allow this operation.

Beretta molds the APX’s frame, which the company calls the grip frame housing, from a rigid, glass-filled polymer, and, judging from the magazine well’s lack of flex when squeezed in the hand, it appears to be quite sturdy. A three-slot section of Picatinny rail is formed into the pistol’s dustcover for the installation of any compatible accessory, and the APX’s squared-off trigger guard was designed to be spacious enough to accommodate a gloved finger. The gun’s textured, almond-shaped magazine release ships from the factory configured for right-handed use, but can be reversed for use by the southpaw minority. Slight indentations have also been cut into the magazine well to allow a firm grip on the magazine’s flared baseplate to be achieved should it need to be forcefully removed from the gun in order to clear a malfunction. Magazines for the new model are not compatible with any existing Beretta handgun designs.

The APX makes use of a replaceable backstrap system that allows the shape and circumference of the grip to be altered in order to fit the hands of multiple users. Each insert not only incorporates the backstrap, but also wraps around the sides of the frame to a significant degree. The gun ships with the Medium insert installed, as denoted by the small “M” molded into its interior, however, Small and Large replacements are also included. An internal backstrap retainer, which must be removed in order to change backstraps, features a hole for the optional use of a lanyard.

Three finger grooves are molded into the frame’s frontstrap, the shallows of which bear stippling comprised of rows of small, relatively sharp, pyramids. Along each side of the frame are two panels with moderately rough skateboard-tape-like texturing, the bottom two of which bear Beretta’s three arrow logo, and the stippling on the backstrap matches that found on the frontstrap. All told, the texturing on the APX is fairly aggressive, which really helps the shooter maintain purchase on the gun during firing, even while wearing gloves.

Located toward the rear on the right side of the frame is a striker-deactivation button. This device allows fieldstripping of the APX to be accomplished without it being necessary to pull the trigger, offering additional peace of mind to those who desire it. To disassemble the handgun using this feature, first remove the magazine and confirm that the chamber is empty. Next, retract the slide slightly and press in on the striker-deactivation button with a small punch or the tip of a ball-point pen until a click is heard. Finally, rotate the takedown lever downward 90 degrees and push the slide assembly forward off the rails. For those not averse to pulling the trigger during disassembly, fieldstripping can more simply be accomplished by: checking that the gun is unloaded, rotating the takedown lever to the downward position, pulling the trigger and pushing the slide free of the frame.

Evaluation of the APX took place in two phases. First, I was among a group of writers invited to a Beretta tactical summit at the O’Gara Training Center in Montross, Va., where we ran the pistol through two days of square-range drills—including low-light maneuvers with a hand-held light and no-light exercises with the assistance of Steiner AN/PVS-21 night vision goggles. We were also given the opportunity to use the gun on paper targets while working with a partner to clear a live-fire shoot house. I tallied somewhere in the vicinity of 600 rounds through one APX at the O’Gara facility.

Later, upon receiving a test sample from Beretta, I ran the second gun through American Rifleman’s standard battery of accuracy and function testing. Through approximately 1,100 rounds between the two test guns, only two malfunctions were encountered—in both instances the APX failed to return to battery after the slide was “slingshot” with the support hand to close the action on a fresh magazine. No issues occurred when the slide release was instead used to accomplish the same action—which, fortunately, does not require much force on this handgun. Apart from this preference (which both test models demonstrated), the pistols fed, fired and extracted without issue.

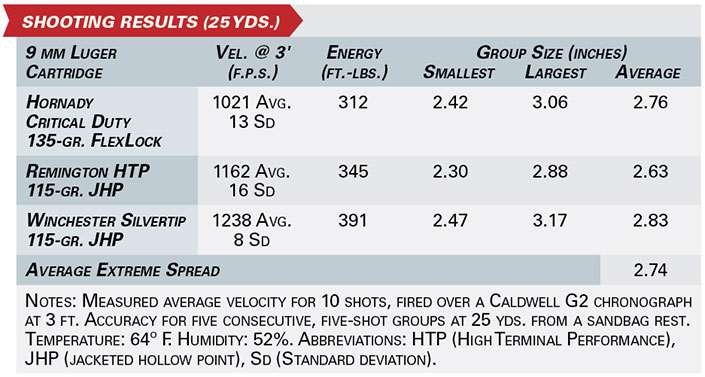

The trigger on the APX broke consistently at right around 6 lbs., 5 ozs., of pressure, after 1/8" of take-up and slight creep. Reset required letting the trigger out by only about 1/4", and was accompanied by a tactile and audible click. Accuracy testing conducted at 25 yds. (tabulated on p. 67) resulted in an average extreme spread of 2.74" between three ammunition loads—more than adequate for a duty sidearm.

Beretta put special emphasis on designing the pistol with a low bore axis relative to the shooting hand, with an eye toward improved controllability, and the effort appears to have paid dividends. In testing, the APX exhibited minimal muzzle rise and mild perceived recoil for a full-size 9 mm. I also found that, when configured with the factory-default Medium backstrap, the gun pointed very naturally for me; transitioning from target to target was instinctive and swift.

While the company has revealed that future additions to the APX line are forthcoming, it remains pretty tight-lipped at this point regarding what form that expansion will take. Tamborino did mention that a Cx4 carbine compatible with APX magazines is among the options that are currently being investigated. Given the inherent modularity of its chassis system, the possibilities are vast, and I look forward to seeing what Beretta has in store for the APX platform.

Beretta has chosen the tagline, “Win The Fight” for its new APX, and I feel that this simple, no-nonsense phrase was a perfect choice to encapsulate such a simple-to-operate, no-nonsense pistol. Every aspect of this gun was designed with only one purpose in mind—to maximize the wielder’s odds of survival should worse come to worst—whether that be in the hands of a soldier, a peace officer or an armed citizen. And after spending a considerable amount of time behind the sights of the company’s newest pistol model, I can’t help but feel that the Beretta family’s nearly five-century-long legacy is in good hands.