At the dawn of the Atomic Age, the U.S. government implemented a policy of geographic dispersion for its small arms manufacturing. This policy, intended to limit the impact of a nuclear attack on domestic small arms manufacturing, led the government to approach International Harvester, a farm equipment producer based in Evansville, Ind., which was located more than 800 miles away from the traditional armsmaking hubs at Springfield, Mass., and New Haven, Conn.

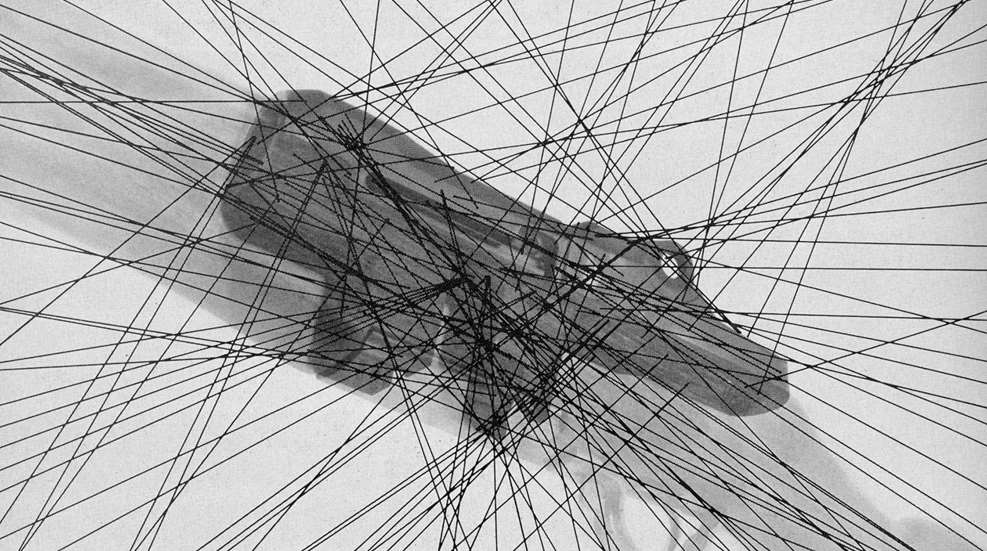

In June 1951, International Harvester was given a contract for 100,000 M1 rifles, with deliveries scheduled to begin in December 1952. Problems plagued the manufacturing process, with International Harvester having to source components from subcontractors and requiring expert help from Springfield Armory to work through manufacturing problems. One of the biggest obstacles in making the M1 Garand was the intricate machining work required to create the receiver.

An article from the Spring 1954 issue of International Harvester Today, the company’s internal magazine, illustrated just how challenging it was to produce this central component. No fewer than 152 machining operations went into the creation of one receiver. Supporting text in the article outlines the “ordeal of the Garand,” in which completed rifles underwent testing at a nearby 100-yard range. Twenty-four rounds were fired for function, then eight rounds were fired for accuracy. All eight shots inside of a 5” circle was a passing grade.