A half-hour after sitting down to learn how Ronnie Barrett built the gun company that bears the family name, a company located in his hometown of Murfreesboro, Tenn., and currently celebrating 40 years in business, he’s shared just one thing you’d expect. No, it’s not a problem of warming up to his topic. Ronnie’s on message, reeling off memories so quickly and enthusiastically that my laptop is practically smoking.

“I was a big shooter, had an Uzi, pistols, rifles and was always looking to collect more. My brother and I shot every Friday and Saturday,” he recalls. “We’d go out in a field, set ’em all out and just shoot. Boy, that was fun.”

“What about .50 BMG?” I ask.

“The first one I shot was the one I made,” he said with a grin. Remarkable, given that for three-quarters of the time he’s been in the gun trade Ronnie has been Mr. .50 BMG, as evidenced by roughly a third of the world’s armies using Barrett .50s in ways that have forever changed modern warfare.

Actually, another non-surprise comes when Ronnie’s son, Chris, joins us. A renowned firearm innovator and businessman in his own right, I met Chris a few years back and thereupon learned about his major role that goes way past “chip off the old block.” No doubt Chris has heard it all before, and, for now, he sits back and lets Senior run.

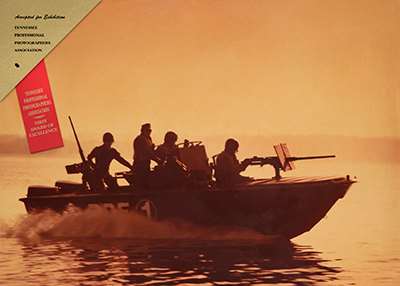

For starters, Ronnie confirms the wild tale about what originally triggered his ambition. “New Year’s Day 1982— I had a photography studio and got a call: ‘Can you come right now? We got a boat on Percy Priest Lake. Need pictures and our photographer didn’t show.’ I said, ‘yes.’”

A .50-cal. Browning was mounted on the bow of the boat, a product of Nashville’s RAMO, Inc., which was hoping that a dynamic image would help them earn a government contract. Though the picture was an award-winner, there would be no contract. Nonetheless, the dominoes were falling.

“I went back to (RAMO’s) Pony Maples and told him I thought I’d make my own rifle. He wanted to sell me one of his for $3,200—a lot of money back then,” Barrett says. “I said [my design] would have to be something easy to play with, that I was thinking about a T-bolt action. Pony said if anyone ever came out with a semi-automatic .50, now that would be a sellable product. So I answered, ‘Well, okay, I’ll design and build one, and if it looks good, you guys can make it.’ Then I went home, and on the dining room table, started sketching how I wanted it to look.”

The lack of engineering or machining experience didn’t slow the young man down. “My father ran a [cabinet business], so I had a background working with tools, and for my photography business had made all the tables, workbenches and props. I was pretty good at drawing, too, so I took those sketches of my semi-automatic to a shop to see if they’d help me make a prototype. They said it looked pretty good, but that I’d need to convert it correctly. I didn’t even know dimensions had to be listed in thousandths, all that,” he said, chuckling.

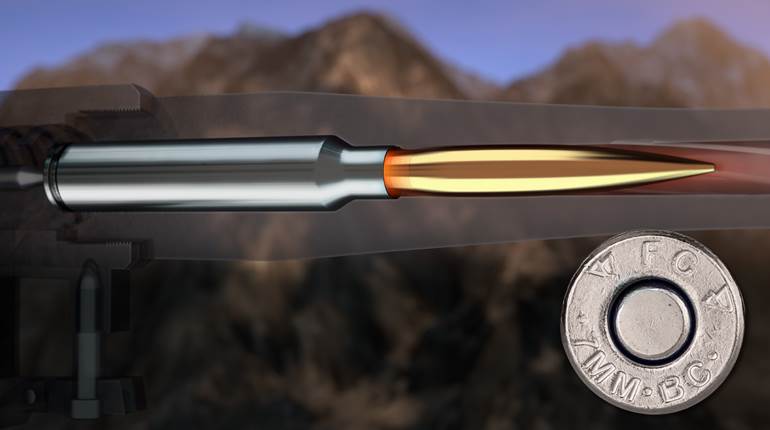

“I learned. Found a machinist, Bob Mitchell, whose small shop had a mill, lathe, grinder and drill press. We’d start at 5 o’clock after our regular jobs and work late into the night. Also, I worked with a fellow from Scotland, Harry Watson, to bend the metal.” A few months hence, Barrett and his mentors had fabricated a shoulder-fired, semi-automatic .50 BMG about 5 feet long and weighing nearly 30 lbs.

“That rifle would shoot a few times, then jam,” Ronnie admits. “It needed several improvements, and so I started a second version before perfecting the first. The second one had a hex steel [frame]. It was a lot less bulky and sexier, and that’s the trademark design we still use.”

“That one I took to the Houston Gun Show,” Ronnie says, “though I hadn’t actually finished it. There was no bolt, just a carrier, so I put a stick in there so you couldn’t pull the action. I ran a video of the first prototype at the show and no one noticed they were two different guns. I took deposits from three people. Then I placed an ad in Shotgun News, cost me $2,300, and got more orders from that.”

In just six months, the budding gun designer created and built two different prototypes, waded into marketing and sold more than expected. “I went back to Pony Maples and said, ‘Here they are.’ But he was sinking everything into trying to get a Navy machine-gun contract. So I just moved on from the idea of working with a manufacturer. I decided to just keep making them myself.”

Juggling demands at the photo studio, Ronnie and his partners launched production. “The house I was renting from my father had an old open-bay garage where I started bending the [frame pieces] and set up a welder after convincing the city to let me run a 220 line in there. I’d bend the steel, and Harry came over to weld everything together. Another friend, Tom Isabon, was making our small parts, bolts and stuff, on a manual mill. We made 30 guns that way, months overdue from orders already taken. I lost money on them and had to raise the price to build another batch. Again lost money, but not as much. Finally made a little [profit] off the third batch. I was learning about investment casting and other ways of doing things that would be more efficient.”

The result was love at first sight for big-gun fanciers, beginning with the now-iconic Barrett profile formed from heavy-gauge steel stampings that comprised the stock and receiver. As Ronnie solved feeding issues, designed a reliable 10-round magazine and tamed the daunting .50-cal. kick with a recoiling action/barrel and a proprietary “arrowhead” muzzle brake, word spread fast. In an early review, American Rifleman noted, “The Barrett M82A1 has found wide favor … thanks to its rugged design, easy take-down and high rate of fire.”

Uncle Sam Wants Barretts

“A fellow named Dick Swan called and wanted a rifle. He was in the industry, making scope mounts for H&K rifles and had designed a black-ops AR,” Barrett explains when asked how he moved into the military realm. “Dick took me under his wing and insisted I ought to be at the AUSA show up in D.C.” Organized annually by the Ass’n of the U.S. Army, this is America’s preeminent showcase for military hardware and related products.

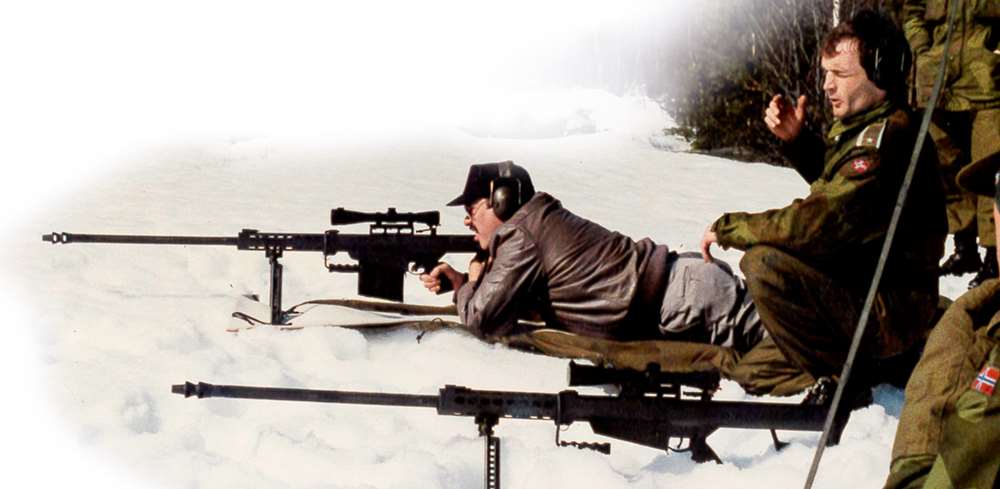

“Dick told me to bring a rifle. Though I couldn’t afford my own booth, he’d try to get me in with a friend selling night-vision gear. We went up to the hospitality suites, and I met the guy and told him I had just the rifle for mounting that night-vision [equipment]; it would make his units look small. He agreed, and so the next day, I waltzed that big gun in through the front door,” Barrett said, laughing at his own audacity. “I displayed it [for] three days, handing out brochures to military officers from around the world. Soon I was getting calls from different countries. Israel was the first seeking information, but Sweden actually put in the first order. They were worried about the Soviet navy and thought our rifle would be the thing for pestering those ships. Before I could fill the order the Soviet Union started falling apart, and so the Swedes ultimately took 100.”

It seems that the first Barretts used in combat were rifles the CIA acquired on the down-low and passed along to Afghan insurgents fighting Soviet occupiers. Though details can be found at barrett.net, Ronnie doesn’t mention it.

“My first sale to the U.S. was to the Air Force,” he recalls, “which wanted it for clearing unexploded ordnance from runways. The 20 mms they were using for that job ripped up the tarmac. The .50 caliber was perfect. Soon I got a call from Quantico (USMC), and then the Army showed interest. That was a time when both had [operators deployed] in Central and South America, interesting stuff.

“An Army major friend soon told me, ‘Now we’ve seen your rifle and we’re going to need lots of them next time [trouble starts].’ And, soon enough, it did.” The inventor paused for effect. “Desert Storm.”

History was about to put the small Tennessee assembly shop on speed dial. “Another Army major got in touch wanting to buy 200 rifles. Eventually, he settled for half that, and I saved 100 for the Marines,” Barrett said. “The UK called and also wanted 100 rifles. Though we didn’t have them, I took the order and the money, and then all of us, about 10 employees, me included, worked all Christmas week to build those 100 rifles. We started at 5 a.m. and went straight through until 11 every night. At that time, the shop was a small building behind my house. On Christmas Day, [a buddy from Nashville] and I were out at the berm on my property, BOOM-BOOM-BOOM, test-firing those rifles headed for Kuwait.

“Gearing up for Desert Storm, the Barrett M82A1 was made an official Marine Corps rifle. At that point, (U.S. Army) SOCOM thought they would transfer money through the Marines to procure their Barretts, but somehow, that meant all the Army special forces who already had our rifles would have to send those back, and nobody wanted that. So the Army also made it official.”

Gulf War troopers soon reported the mind-boggling ability to neutralize trucks, armored personnel carriers and other hard targets at ranges well over 1,000 yards. Soft-target engagements were likewise far-reaching, thus spawning discussion on the essential role of Barrett’s mighty .50: Anti-materiel? Anti-personnel? Versatile platform? The consensus is that this new force-multiplier marked a turning point in small-arms development, one that gave armies greater reach with greater mobility than ever.

In less than 10 years, a weekend plinker, self-taught engineer and gifted entrepreneur parlayed a sudden zeal to create his own rifle into respect from the world’s elite riflemen and the military brass responsible for defending national interests. As if it’s nothing extraordinary, Ronnie shrugs and says, “I could always do anything I wanted. That’s just my nature. As an older man, I know now if God wants something done, He’s going to get it done. A lot of times with the least likely people. That’s how you know it’s God.”

Barrett Firearms has been a must-have military supplier ever since. About 75 State Department-approved countries have issued Barrett rifles to their troops, and that includes all U.S. branches, save for the new Space Force. The big M82A1, formally designated the M107 by the U.S. Army in 2002, still accounts for the lion’s share, but other designs have garnered interest, too, most recently the bolt-action Mark 22 Mod 0 (MRAD). Its official adoption by USSOCOM in 2019 was an unprecedented second strike of lightning, making Ronnie and Chris Barrett the only father-and-son team to design official U.S. service rifles.

But the connection with U.S. Armed Forces goes beyond business. Soldiers often share meaningful experiences with Barrett personnel with a brand-loyalty fervor other firms must envy. Take one particular viral tale that keeps crashing the internet beyond just military and firearm-enthusiast sites. Is it really true that an American sniper facing a battlefield malfunction dialed up the company’s help line directly from the “sandbox?” Ronnie rolls his eyes and leads his visitor out to the factory floor. “This is Don Cook,” he announces, “the man who took that call.”

“Yep, there was live fire going on, and lots of it,” nods Cook, himself an ex-Marine. “The caller needed to get back in the fight, but his rifle’s trigger was stuck. After he explained, it was clear the mainspring housing ears were bent. I’d seen that before, and I described how he could remove the cover and use the bolt carrier to hammer them back into place. Right away, I heard him working on it. Soon I heard louder shooting—that was him!—and he yelled, ‘Thanks!’ then started firing again before I could even ask what unit he was in.”

But the matter didn’t end there, as Cook demonstrates by grabbing an M107 lower receiver to point out how the company subsequently re-designed and beefed-up the mainspring housing to prevent such a problem from occurring again. Ronnie echoes Barrett’s commitment to support military customers and the relationship it shares with them. “I love it. It’s allowed me to meet some of the world’s finest people. When we meet up, many soldiers want to shake hands or give us a hug; some shed tears telling how our rifles have saved their lives.” He takes a deep breath. “It is very rewarding.”

Branches On The Family Tree

Coinciding with the M82 military sales spike in the early 1990s, Barrett began diversifying with moves into the bolt-action category. Despite the different operating system, the successive Models 90 and 95 were near-stylistic twins of their semi-automatic forebear. These 23-lb. behemoths came with pipe-like 29" barrels and were chambered solely for .50 BMG. Both models sported onboard bipods, detachable magazines the size of 2x6s and wedge-like muzzle brakes. At decade’s end, the single-shot Model 99 emerged, and American Rifleman’s review commented on a change in “philosophy,” represented in the “entry-level market Barrett hopes to tap with a match-grade rifle well below match-grade cost.”

Yet a greater change went unremarked, in that it was the debut contribution from a young staffer who would soon become chief designer. Chris Barrett had jumped into full-time duty upon high school graduation in 1996 and was barely out of his teen years at the release of the M99. It was just the beginning of a lengthy creative resume that fueled company growth, added to its fame and ensured shooter loyalty. Noteworthy contributions include:

• The .416 Barrett cartridge (2007)—using a necked-down, shortened .50 BMG case that delivers more downrange energy than its parent;

• AR-pattern carbines, culminating in the REC7/REC10 family (2008)—small-caliber platform in both gas-piston and direct-impingement versions: applications include law enforcement, personal protection and combat rifles;

• The Model 98B precision rifle in .338 Lapua Mag. (2008)—a template for today’s sniper rifles; and

• The MRAD/Multi-Role Adaptive Design bolt-action rifle (2011)—functional versatility, including caliber interchangeability, allows operators to tailor their rifles to changing mission environments. SOCOM-contract rifles go from 7.62 NATO and .300 Norma to .338 Norma.

Along the way, father and son have both served stints as company president, but eventually decided the administrative demands didn’t allow the best use of their talents. Nowadays, former fiscal officer Sam Shallenberger sits at that desk. Regardless of their spots on the organizational chart, Ronnie, Chris and others have worked together behind the scenes to modernize a company whose dining-room-table and garage-shop origins were brilliant in formative times but had become outdated. In this proactive push, engineers switched from hand-drafted blueprints to CAD software and 3D modeling; CNC machinery replaced earlier tooling and Chris gave the factory a lean-manufacturing makeover that simultaneously tightened production efficiency and quality control.

Nonetheless, Chris asserts, “My greatest accomplishment was setting us on some directives that have had big payoffs and allowed us to recruit top guys. As managers, we’ve gone from handling people to developing people. There’s a plan and a backup for everything we do and for every employee. We are a self-perpetuating company. That’s helped us create a brand synonymous with service, one that’s better than ever at dealing with red tape and satisfying customers.” If there was a problem, Barrett fixed it.

Awards and recognition have come in spades and from different directions. Just a few of the most prestigious: a 2005 U.S. Army “Top Ten Greatest Inventions” nod for the M107; 2006 Entrepreneur of the Year from global accounting giant Ernst & Young; International Organization for Standardization 9001 certifications for quality management; and the Tennessee legislature naming the Model 82 the official state rifle.

Furthermore, Barretts have twice claimed Rifle of the Year in NRA Publications’ Golden Bullseye excellence program, and Ronnie was individually honored with its distinguished Pioneer award in 2010. In fact, Ronnie is a long-time NRA Director and has been among the leading vote-getters every time he stands for election. Visitors to his office can’t miss the NRA Board service plaque mounted at eye level next to the main door. “NRA changes elections, and if it wasn’t for NRA … where would our country be? We’re on the move, and with the great board now, we’re stronger than ever,” he remarks, then winks, adding, “’Course, I think it’d be smart to re-locate NRA’s incorporation papers to Tennessee.”

A Long-Range Forecast

Ronnie Barrett sifts through stacks of old color snapshots, spreading a handful out on his desk. “Look at that,” he sighs. “Oh my.” He turns up one with schoolboy Chris and dad in dated camouflage, posing with shotguns in hand. The next shows a fellow wearing a dress shirt and pants, busy at a press bending steel into a lower receiver. There are countless more that help make clear why this 40th anniversary is such a proud milestone.

Enjoyable as the memories are, our conversation also reveals the Barretts are locked onto their next decade and beyond. By contrast with other top firearm brands, however, that outlook doesn’t hinge on a steady parade of new products.

“We have designs that haven’t come out yet, but they’re ready; maybe a new rifle later this year,” hints Ronnie. He won’t say more, but allows, “… there will also probably be [accessory introductions] in the near future. Right now, our time is occupied with the two [service] rifles, the MRAD Mark 22 and the M107. We’re sold out until 2024, running full capacity. Some years, we have a lot of government business. Other times, we run with our civilian business.”

Chris Barrett adds perspective. “We went down that [new-product-driven] road for a while because we are creative. I don’t want to be critical, but that approach takes a lot of money, machinery and a very different culture than we have here. I don’t see us making, say, thousands of pistols at a $20 margin or other commodity products. There’s always someone who will make them cheaper. But, in our specialty, no one’s been able to compete. It’s why we lead the pack.

“We’re dedicated to making supreme long-range things. That’s what we do, and within our niche, we certainly are working on new things. Extreme long range is who we are and where we’re going,” he says. “Over the next 10 years, Barrett will lead the way in launching projectiles that hit targets at distances farther than ever thought possible.

“With what’s going on now in the world, everyone can see the need, both for military and civilians, who, of course, have the right to such arms.”