Frank DeSomma didn’t set out to be a gun designer; he was just an engineer in the aerospace industry who happened to be a gun enthusiast. The job of a process engineer is to be a troubleshooter and to discover better ways of doing things. Fifteen years ago, DeSomma was working on FALs with his son when the troubleshooter in him took over—he realized that a piston operating system such as the one used by the ubiquitous Belgian battle rifle, the FN-FAL, was just what the AR-15 needed. Thirty hours of concept work later he had a design, and within a month he had a firing prototype. Before he knew it, Patriot Ordnance Factory was born.

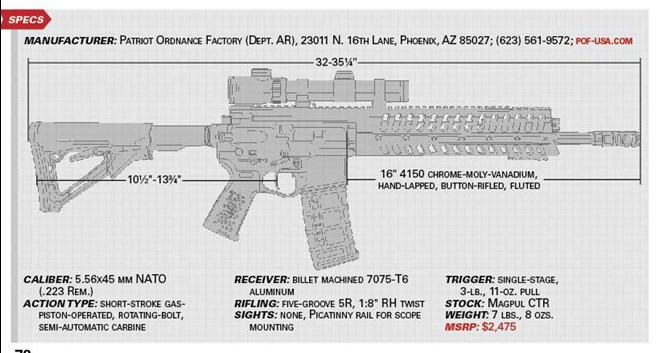

The name Patriot Ordnance Factory isn’t just some attempt to capitalize on Second Amendment fervor to sell guns—this company and its owner walk the walk. Every component in POF rifles is either made in-house by POF or is sourced from an American manufacturer. Even the raw steel and aluminum used in POF’s manufacturing processes come from U.S. sources. Most of the major components, including the upper and lower receiver, the rails and the bolt carrier, are produced in-house in POF’s Phoenix, Ariz., facility. The 5R-rifled barrels are produced by Rock Creek, the furniture is from Magpul and various small parts come from a variety of top-tier vendors.

From the outside, most AR-style rifles look pretty similar. What many consumers don’t realize is that, regardless of brand, the majority of AR components are produced by a small number of manufacturers and then assembled by the company whose name is stamped on the receiver. That isn’t a bad thing; it’s merely the reality of cost-effective manufacturing. Because of DeSomma’s engineering background, he and his team tackled the design of the entire AR one piece at a time, looking for ways to make things stronger, make them operate more smoothly with less friction and drag, and even produce the gun with fewer moving parts. The result is a product featuring seven new patents, with more pending, and reliability that has become highly regarded.

The most outwardly innovative component of the POF design is the piston operating system. Unlike Eugene Stoner’s original design that uses a gas tube to direct propellant gases into the bolt carrier key to cycle the bolt, DeSomma’s design uses a piston and operating rod to transfer energy back into the bolt and force it rearward. The benefits of the piston are to keep heat and carbon out of the action where they can cause reliability problems. Unlike most other piston designs, the POF operating system uses few moving parts and no return spring. Extreme heat is the enemy of springs, and since piston designs keep the heat near the barrel instead of inside the chamber, DeSomma believes that introducing a spring into the piston operating system is a problem waiting to happen. The POF piston system works on the same principle as “Newton’s Cage”—the metal ball display often seen sitting on desks that demonstrates the transfer of energy—one ball swings down and transfers its energy through several immobile balls resulting in movement of the final ball on the opposite side. The piston on a POF only moves 3/8" when the rifle is fired, but the energy created by that movement is enough to send the bolt carrier rearward to cycle the action.

Much of POF’s process of building a better AR centers around heat. Rifle cartridges produce lots of heat by nature, an unavoidable fact caused by the rapid burning of propellant. The heat is going to exist; however, it is where the heat is directed and how it is dissipated that separates one design from another. The company employs various features to keep heat away from the receiver and to cool the gun as rapidly as possible. For starters, the piston design requires less gas than most others, so the gas port is smaller in diameter—less gas being siphoned from the bore means less heat to contend with. The piston design works without rings, which have a tendency to retain heat, so additional gases are allowed to escape. The barrel itself is cooled by an innovative aluminum barrel nut that physically draws heat away from the steel, and pronounced flutes in the barrel provide additional surface area for heat dissipation. In an independent torture test performed a few years back, a POF was subjected to an unrealistic schedule of full-automatic fire: a series of Beta Mags were used to fire 1,000 rounds within minutes. Though the gas block and muzzle brake reached temperatures of nearly 700° F, the chamber temperature of the POF never climbed above 122° F—the risk of a temperature-induced “cook off” with a POF is virtually nonexistent.

In DeSomma’s mind, if the AR has one Achilles’ heel, it is extraction. Though the AR is often compared unfavorably to the AK when it comes to reliability, the AK has a geometrical advantage that the AR does not: the greater taper of the 7.62x39 mm cartridge. This taper not only acts as a funnel when the cartridge is feeding into the chamber, it provides a tremendous advantage in extraction. By comparison, the more “modern” 5.56x45 mm and 7.62x51 mm NATO cartridges have minimal taper. Once fired, the expansion of the case head creates a press-fit seal between the cartridge case neck and the AR’s chamber in addition to the friction caused by the nearly parallel planes of the case body and the chamber wall. The result is a reasonably common occurrence of stuck cases in the AR series of rifles. A stuck case is a serious malfunction that can put a finely tuned rifle out of action in the midst of a battle.

POF’s solution to the extraction issue was literally to stick a square peg in a round hole. What it calls E2 extraction technology, is a series of four channels that run parallel with the cartridge in the neck of the chamber. Set in the form of a square when viewed from the rear of the chamber, the channels allow the rapidly expanding propellant gases to flow rearward into the shoulder of the cartridge, which breaks the mechanical seal between the case neck and the chamber wall and assists the case in its rearward travel out of the chamber. Think of it as using a long screwdriver to break the impossible seal between two five-gallon buckets stuck inside of one another. The San Bernardino, Calif., Sheriff’s Office tested a full-automatic 14.5"-barreled 7.62x51 mm NATO POF carbine for its Special Enforcement Detail in 2013. The testing put 35,480 rounds through the carbine (which did not experience a single malfunction until round 23,500 when the buffer spring gave out), and they did not experience a single failure to extract. The E2 technology is standard on all Gen 4 POF firearms. In case you’re wondering, fired cases are fully reloadable, just a bit dirty from the escaping gases.

The AR-15’s bolt carrier has two additional areas that can cause reliability and wear issues—the gas key and the cam pin. The gas key on a direct-impingement AR is the link in the chain between the propellant forces surging through the gas tube and the working parts of the receiver. The gas key is screwed and staked into place to prevent it from working loose under thousands of firing cycles. If and when the gas key comes loose, the rifle ceases to function. Due to the piston design, the POF does not use a gas key. The engagement surface that sits in its place is a homogenous part of the bolt carrier and therefore cannot work itself loose. The cam pin on traditional ARs has a rectangular head, which rides inside a slot in the upper receiver. Eventually, the hardened steel surface of the pin reciprocating on the softer surface of the aluminum receiver can cause undue wear on the firearm. POF mitigates this friction by using a roller cam pin that rolls like a wheel through the receiver groove with minimal friction. POF’s bolt carrier groups are all either nickel-boron- or NP3-coated, which further reduces friction between the components and makes them easy to clean.

The Gen 4 P415 carbine I received for testing and evaluation came equipped with a 14.5" barrel topped with a pinned and welded muzzle brake to bring the length up to the NFA minimum 16". This moderate barrel length provides enough velocity for solid external and terminal ballistics but allows for a very manageable overall size. The barrel is black nitrided inside and out, which eliminates the need for chrome lining and actually raises the Rockwell hardness of the steel—the system components are also nitrided. POF rifles and carbines are available in different colors, including the Burnt Bronze Cerakote finish on the major parts of my test model.

When AR-style rifles lost the carry handle, they gained tremendous versatility but gave up some rigidity—POF’s design seeks to regain some of that by employing a two-piece upper receiver. The slotted free-float fore-end of the P415 extends over the top of the upper receiver, providing an uninterrupted Picatinny rail as well as bridging the major components together mechanically. Small rail sections can be placed in various locations on the fore-end as desired, without the weight and abrasiveness of a fully-railed design. The gas system is easily removed from the front of the fore-end and does not require the tube’s removal so optics do not need to be re-zeroed after the gas system is serviced. The gas plug’s orientation determines whether the system is in “normal” or “suppressed” mode.

All Gen 4 POF firearms are equipped with fully ambidextrous controls. The selector/safety, slide-stop and magazine release can all be actuated from either side of the receiver. The slide stop is in its traditional position on the left side of the receiver, but an additional button is located inside the trigger guard to lock the bolt to the rear. A button above the right-side magazine release is used to drop the bolt into battery, and an additional magazine release is positioned on the left side of the lower. This system is both intuitive and practical, and allows the carbine to be used from either shoulder with equal effectiveness.

There’s no doubt that the POF is designed to perform, but it was my job to make sure that the gun works as advertised. In order to fully evaluate the P415, I enlisted the help of a friend whose experience in U.S. Army Special Operations spans four decades and includes numerous combat deployments in various corners of the world. I wanted his input because of his significant operational experience using not only the direct-impingement M16 and M4, but also the gas-piston-operated HK416. The sergeant major and I spent an entire day at the expansive ALS Training Facility in Perry, Fla., running the P415 through a variety of ranges including an urban “shoot house.” Once we mounted an Aimpoint optic and established a zero, I rapidly expended three 30-round magazines into the 100-yd. steel target before making the carbine safe and removing the bolt carrier. Despite firing 90 rounds in under two minutes, the bolt was cool to the touch. We fired hundreds of rounds of various types of military and commercial ammunition through the P415 and experienced no malfunctions of any kind.

Firing the POF is slightly different than the feeling of a direct-impingement AR due to the difference in the operating system. A combination of less bolt carrier impact on the buffer and an effective muzzle brake results in slightly less muzzle rise than typical AR-style carbines. After hours of running the POF through its paces, I asked the sergeant major for his feedback. His only comment was, “When I buy it, I’m gonna’ put an ambi charging handle on it.” A pretty solid endorsement from a guy who has used just about every modern combat carbine on the planet.

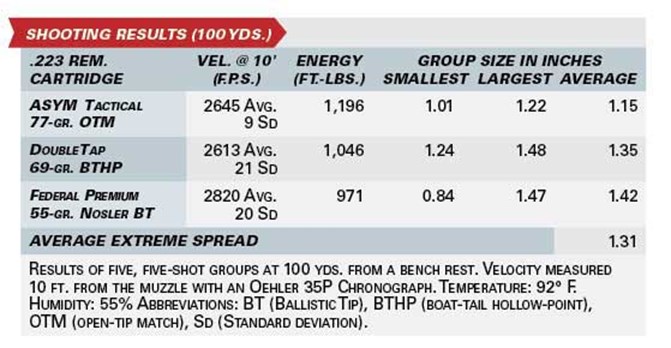

Following our practical testing, I fitted the carbine with a magnified optic, did a cursory bore cleaning and performed the formal accuracy tests. The crisp, single-stage trigger broke at under 4 lbs. and made shooting from the bench an easy task. POF’s piston system is designed with built-in tolerances to allow it to free-float from the barrel. Despite temperatures in the 90s, the carbine’s zero did not show any signs of shifting under the heat of sustained firing.

From my experience, it appears that Frank DeSomma and his team at Patriot Ordnance Factory have taken the platform he calls “America’s Rifle” and notably improved it. The result of their efforts is an accurate, ergonomic and utterly reliable carbine ready for just about anything the user throws at it.