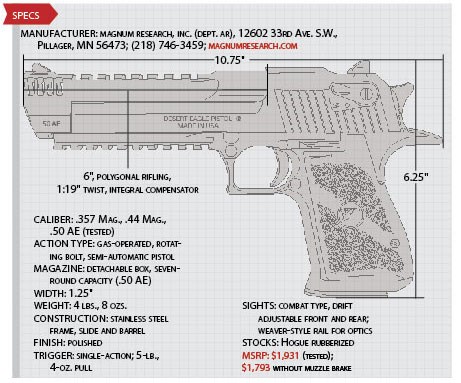

Boasting precision engineering, innovative design and impressive accuracy, the Magnum Research, Inc. (MRI) Desert Eagle continues to fascinate connoisseurs of fine firearms and capture the imagination of millions with its appearances on the big and small screens. With users, the gas-operated semi-automatic pistol has garnered a reputation not just for its big-bore chamberings, but also for its versatility. The platform is easily configured to suit a specific purpose by simply swapping barrels of various lengths and calibers— .50 AE, .44 Mag. and .357 Mag.—along with magazines and, if necessary, bolts. Myriad finishes, from 24-carat gold to matte black have long been a hallmark of the big bird. And now other, more functional, options are available. Earlier this year, MRI began producing Desert Eagle models in stainless steel, and has introduced a new integral compensator to help tame the savage recoil of the .50 AE cartridge.

Boasting precision engineering, innovative design and impressive accuracy, the Magnum Research, Inc. (MRI) Desert Eagle continues to fascinate connoisseurs of fine firearms and capture the imagination of millions with its appearances on the big and small screens. With users, the gas-operated semi-automatic pistol has garnered a reputation not just for its big-bore chamberings, but also for its versatility. The platform is easily configured to suit a specific purpose by simply swapping barrels of various lengths and calibers— .50 AE, .44 Mag. and .357 Mag.—along with magazines and, if necessary, bolts. Myriad finishes, from 24-carat gold to matte black have long been a hallmark of the big bird. And now other, more functional, options are available. Earlier this year, MRI began producing Desert Eagle models in stainless steel, and has introduced a new integral compensator to help tame the savage recoil of the .50 AE cartridge.

According to Frank Harris, vice president of sales and marketing for Kahr Arms (the company that also owns Magnum Research), “Americans love stainless steel for its good looks and ease of maintenance. It was the next logical step in the evolution of the Desert Eagle.” But offering the gun in stainless steel wasn’t as easy as one might think, and Magnum Research engineers spent years finding the right blends of stainless steel to prevent galling between the frame and slide. Three different grades are used in the frame, slide and barrel forgings, including 17-4 Ph—the same high-quality stainless steel used in surgical instruments.

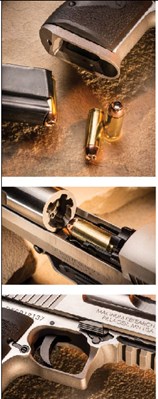

The result is a strikingly beautiful gun, expertly polished and possessing the corrosion resistance that any hard-working gun should have. New for the stainless Desert Eagle is a segment of Picatinny rail at the bottom of the frame. Designed for attaching lights or lasers, it gives the gun a modern appearance that should prove practical for those carrying it afield. A Weaver-style rail is machined integrally with the barrel, providing a solid optic-mounting platform. Also new for the stainless Desert Eagle is an integral compensator. Four ports are neatly machined into both sides of the barrel and are designed to expel gas upward to counteract muzzle rise during recoil. It’s a simple and effective design that Harris says, “Allows people to do more shooting comfortably. We wish we’d thought of it before.” Though the new Desert Eagle has some refinements the original gun didn’t have, there’s not much difference mechanically between today’s gun and the original Desert Eagle.

Magnum Research founders Jim Skildun and John Risdall started the long and difficult process of turning mechanical drawings into a living, fire-breathing hand cannon in 1979. In 1985, full-fledged production of the Desert Eagle started in Israel. Through the years, pistols were made both in the United States and Israel. Kahr Arms purchased MRI in 2010, and guns are currently produced at the Pillager, Minn., factory with production sometimes augmented by Israel Military Industries (IWI) to satisfy demand.

From the beginning, the Desert Eagle has been one of the most versatile handgun platforms available. Between the various barrel lengths and calibers, owners can assemble multiple configurations with a minimium of fuss —.357 Mag. uses a different size bolt than the .44 Mag. and .50 AE, so that requires a bolt swap—including barrel lengths of both 6" and 10" in all three chamberings. Despite the caliber options, the big gun sells best in its appropropriately large-caliber chambering. According to Harris, “It seems like the Desert Eagle’s appeal is its big bore, and the largest percentage of buyers go right to the biggest chambering. The typical buyer is a collector—someone fascinated with the Desert Eagle’s design and power. Others have a much more practical need because they live in or hunt in bear country.”

The Desert Eagle is one of just a few successful gas-operated handguns, and though the gun is lauded for its innovation, some of its design features are not exactly unknown in the firearm world. The Desert Eagle uses a short-stroke piston for operation. When the gun is fired, gas passes through a hole underneath the bore and into the gas cylinder where it pushes the piston rearward. Enough energy is imparted on the slide to drive it rearward where the bolt unlocks after the pressure subsides and the extraction, ejection and feeding cycle begin. If you’ve ever used or studied the M1 carbine this may sound familiar to you, and its operation was most likely the inspiration for the Desert Eagle’s designers. The .50 AE cartridge requires a robust locking system, and the Desert Eagle utilizes a rotating bolt, not unlike that of the AR-15/M16 family of guns, which locks into the barrel extension to provide a solid lockup during ignition. That lockup is likely one reason Desert Eagles have a well-earned reputation for accuracy. In fact, my test sample shoots better than many of my more expensive hand-built M1911s. In addition, MRI’s design utilizes a fixed barrel that does not move when the slide cycles. Also aiding accuracy is polygonal rifling, which MRI claims increases velocity because it achieves a better gas seal on the bullet with less deformation. Without the sharp edges of conventional lands and grooves, that can gouge a bullet’s jacket, most residue can be cleaned from the barrel with a wet patch and very little elbow grease.

Even the most accurate pistol would be difficult to shoot well without a decent trigger. In a heavy gun that fires a powerful load, a safe trigger of hearty design is needed. MRI’s solution is both safe and a delight to shoot. The Desert Eagle possesses a single-action trigger with a decidedly two-stage feel to it. It breaks cleanly and crisply at 5 lbs., 4 ozs. with very little overtravel and is adjustable. For a heavy-recoiling pistol, being able to prep the trigger before the hammer falls makes a great deal of sense. Users can adjust the trigger by inserting a screw driver through the magazine well to turn the Adjustable Trigger Mechanism (ATM). There is a slide-mounted, ambidextrous thumb safety on the single-action, semi-automatic. In use I found it far easier to engage and disengage with the off-hand as opposed to using my strong-hand thumb from a firing grip. In any event, the gun’s manual recommends carrying it with an empty chamber.

The appearance and feel of the Desert Eagle is like no other gun I have ever fired. Weighing a hefty 4 lbs., 8 ozs. and possessing a long and thick grip that feels more like that of an pneumatic power tool than a pistol, there is nothing petite about this mighty .50 AE. While the grip shape is determined by the huge magazine that holds the fat cartridges, seven for the .50 AE, its girth spreads the recoil over a larger surface area, and there are no sharp edges to bite the shooter. The frame also possesses a large tang or beavertail to protect the shooter’s hand from the slide. Also aiding recoil mitigation, my test sample included the brand new integral compensator. In the past, MRI offered the Desert Eagle with a compensator that added almost 24 ozs. of weight to the gun and made it longer, ruining its balance. The new integral eight-port compensator actually makes the gun lighter, contributes to less muzzle flip and gives the gun great balance.

Shooting this behemoth was not a pleasant experience—at least at first. I started by shooting the accuracy portion of the evaluation from the bench. Firing from a seated rest using a Millet Benchmaster for support, I found the wrist-wrenching recoil and muzzle flash a bit much. Remember that the energy generated by the .50 AE cartridge is roughly four times that of a .45 ACP. Also, the MRI manual emphasizes that shooters must use a firm grip for the gun to operate properly. At first I tried to muscle the gun using isometric pressure but found the resultant trembling was not conducive to accuracy. I ended up pushing into the gun, leaning as far forward as possible and locking my wrist and elbow so my shoulder would absorb as much of the recoil as possible. I used my left hand to apply pressure to the front of my right hand. With this technique my groups improved immediately and the Desert Eagle wasn’t such a bear to shoot. Incidentally, I have fired another Desert Eagle, also in .50 AE, but without a compensator and estimate that feature accounts for a 25 percent reduction in muzzle rise.

As my shooting continued, I became more and more comfortable with the gun’s recoil and blast. So much so that I made a second range trip because I was convinced that my original groups were not on par with the Desert Eagle’s intrinsic accuracy. I was able to relax and concentrate on sight alignment and trigger press. After more than 100 rounds, the once-daunting hand-cannon became much less intimidating and was actually fun to shoot. My single best group was fired with MRI’s 300-gr. JHP and it measured just 0.95". Average group size for the three loads tested is just about 1½", and I think that’s pretty darned good for a production pistol chambered for the teeth-rattling .50 AE cartridge. Reliability throughout my testing was flawless—there were no stoppages of any kind.

Disassembly of the Desert Eagle is quick and easy and requires no special tools, though MRI supplies each gun with its 5-in-1 tool. To begin, remove the magazine and clear the chamber, then lower the hammer and pull it back slightly until it clicks into its semi-cocked position. Place the manual safety into its “safe” position. On the left side of the frame, just above the front of the trigger guard, is a barrel lock pin. Press the pin while swinging the barrel lock on the right side of the frame counter-clockwise. Pull the barrel slightly forward until the frame releases it. The slide can now be drawn forward and removed along with the recoil spring unit. Now the gas piston can be removed for cleaning. Use the 5-in-1 tool for cleaning the gas cylinder. For reassembly, lay the slide upside down on a level surface and insert the gas piston, making sure the piston shaft recess is facing the slide recess. The recoil spring plate lug will capture that part and hold it in place. Keep those parts positioned while placing the slide back on the frame. Insert the barrel’s locking lug into the frame’s recess and push against the barrel from the muzzle end and hold the barrel assembly against the frame while swinging the barrel lock clockwise to its closed position. Check the slide for proper function.

The new MRI Desert Eagle in stainless steel is an impressive gun. From its hearty design to its precision machining to its tack-driving accuracy and overabundance of power it is likely to continue intriguing enthusiasts for decades to come.