At the beginning of World War II, Germany created a new standard in submachine gun (SMG) design with MP 38/40 series of Maschinenpistole. Featuring a compact, metal and Bakelite design with an under-folding stock, Heinrich Vollmer’s 9 mm SMG quickly became the envy of friend and foe alike. As the Blitzkrieg raged through Poland, then most of Western Europe, and then the expanse of the Soviet Union, the MP 38/40 was a prime firearm for German infantry, paratroops and vehicle crews.

The new design spawned a line of “second-generation” SMGs, often made in a particularly simplistic fashion, with mass-production economics in mind, but deadly, nonetheless. Most notable of these designs was the British Sten gun, a crude, thoroughly unattractive little 9 mm bullet-sprayer that was called all kinds of rude names by the normally polite British. But jokey monikers like the “Stench Gun” aside, the Germans weren’t laughing while they were being shot by the surprisingly effective Sten guns in the hands of British and Commonwealth troops, and a host of European resistance fighters.

(On a personal note, I, too, made derogatory comments about the Sten gun, until I fired one. The late Dr. Edwin Libby handed me a Sten MKII at a machine gun shoot in Maine, and from the first shot, I found it to be easy to shoot and very accurate. The whole thing didn’t seem possible, and I thought I looked ridiculous with the strange and tiny SMG on my XXL frame, but Dr. Libby commented: “You look like you were born to shoot that little gun!” You can log that experience into the strange-but-true file, and if you get the chance to shoot a Sten, it is well worth the time and trigger pull.)

Often overlooked when looking back on the Sten gun is the tremendous breakthrough the British achieved in the speed of the weapon’s design—just 36 days between the initial concept and first prototype of the Sten Mark I, and its incredibly low cost (about $10-$11 per gun). Approximately 3.7 million Sten guns were completed during the war years with peak production reaching about 47,000 per week.

The Sincerest Form Of Flattery: Gerät Potsdam

By the late summer of 1944, with the Allies at Germany’s doorstep, the Third Reich’s propaganda minister Josef Goebbels was no longer talking about Nazi supremacy on all fronts, but rather about the potential strength of a German resistance to Allied occupation.

"The enemy (invading German territory) will be taken in the rear by the fanatical population, which will ceaselessly worry him, tie down strong forces and allow him no rest or exploitation of any possible success.” —Josef Goebbels

At this time, Reichsführer SS Heinrich Himmler was preparing Unternehmen Werwolf (Operation Werewolf), which was initially intended to be an organization of well-trained commandos operating behind Allied lines. The Werwolf men would wear German uniforms and conduct themselves as legitimate military units within the control of the German High Command. But the Werwolf concept soon began to break down. Himmler selected SS Obergruppenführer Hans-Adolf Prützmann to oversee the operation, and about the best things that were said about Prützmann was that he was “vain, idle and boastful.” Meanwhile, a strange weapons procurement program began, presumably for the Werwolf operators.

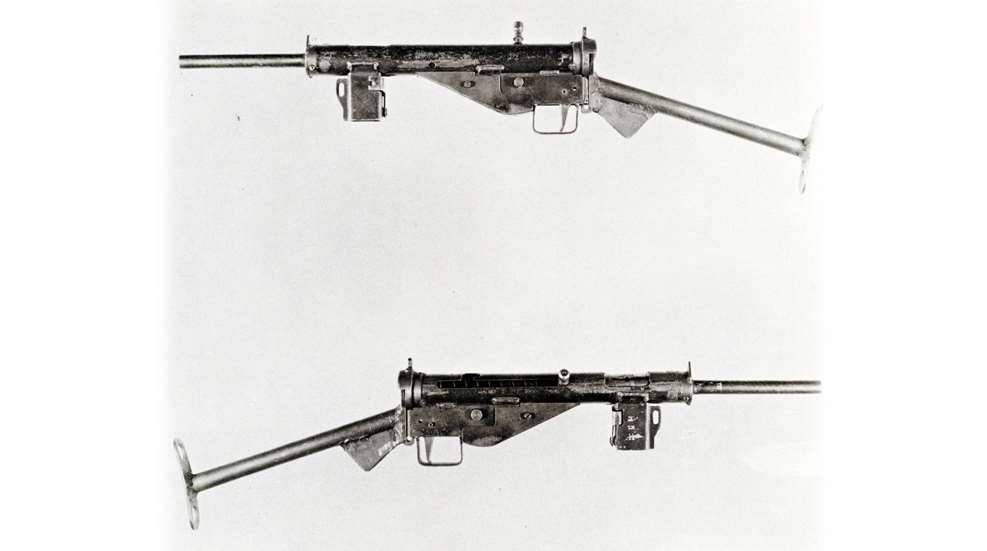

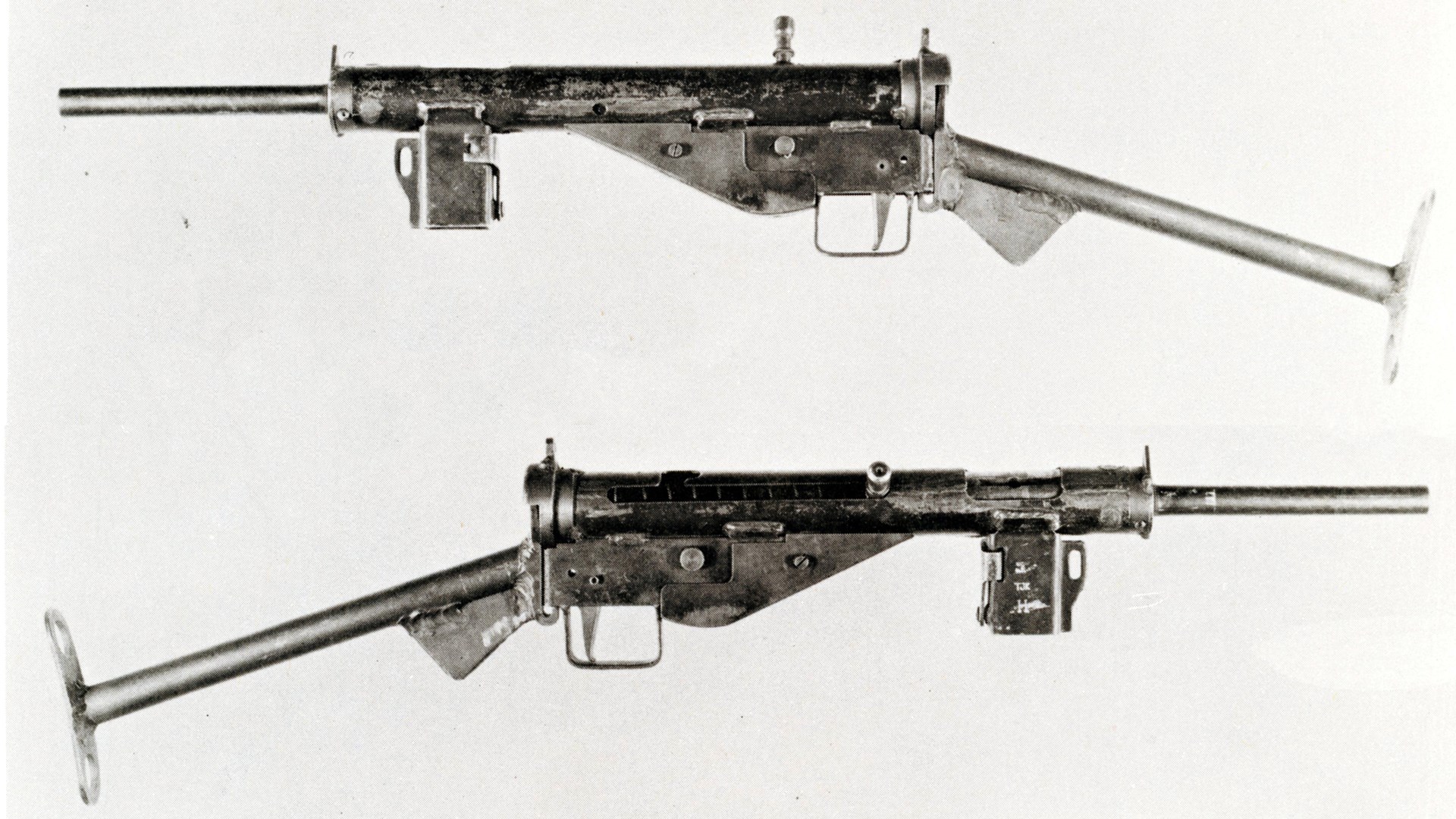

In late 1944, Mauser (Oberndorf) was contracted to produce copies of the Mk II Sten gun. Strangely, these were to be exact copies, indistinguishable from British originals. A pair of British Stens were provided, titled MP 749 (e) in German service. The request for 28,000 Sten copies was urgent, and Mauser’s Oberndorf facility quickly tooled up to make the fakes. Within six weeks, and approximately 10,000 of the Gerät Potsdam (Potsdam device) were made.

With regard to the Gerät Potsdam, the famous Dolly Parton quote, "You'd be surprised how much it costs to look this cheap!" comes to mind. While the country music legend wasn’t talking about the Gerät Potsdam, her quote is entirely accurate. When you tell the folks at Mauser that you want an exact copy of the Sten Mk II, that’s what they will do for you. They will also make the copies in a hurry if you are willing to pay the upcharge. And that is exactly what happened. However, the cost of producing an essentially indistinguishable copy of the Sten, a gun the British worked incredibly hard to construct at just $10 apiece, ended up costing the Germans nearly 1,800 Reichsmarks per gun—about $450 apiece at that time!

The purpose behind the Gerät Potsdam was murky at best—it is mostly thought that the precisely copied Sten guns with British markings were meant to be air-dropped behind Allied lines to equip German guerrilla units (possibly Werwolf operatives). By the end of 1944, any “behind-the-lines” work would have been conducted in Western European nations firmly under Allied control.

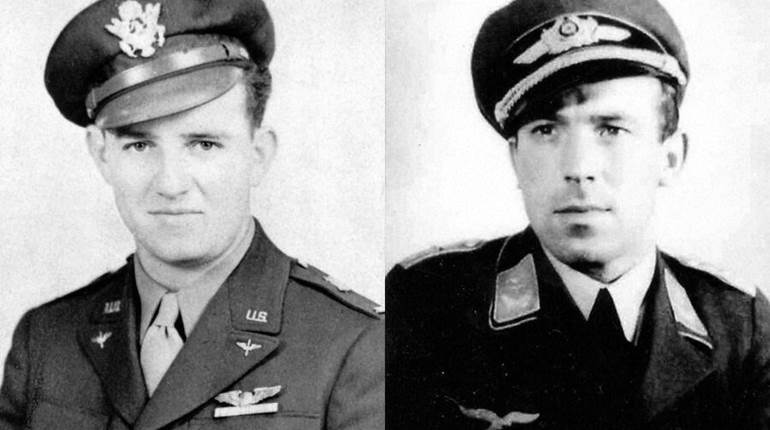

Consequently, the thin ruse of lookalike British SMGs seems to be in complete contradiction with the outrageous cost to produce them. Their use in combat is undocumented, but their performance would be the same as the Sten Mk II. We’ve included a couple of images of a “Sten Mk II” in strange hands at that time—photos that ask more questions than they answer. In the end, it is a tiny nuance in the history of World War II firearms, one driven by a ridiculous notion as the Third Reich crumbled under the weight of its own insanity.

As for the "Werewolves," the organization morphed into a loose network of Nazi agents, saboteurs and assassins, operating on a small scale into 1946. U.S. and British intelligence decided that as early as the summer of 1945, the Werwolf agents did not pose a significant threat to the occupation forces, despite whatever arms they may have available.

Beyond Crude: The Gerät Neumünster

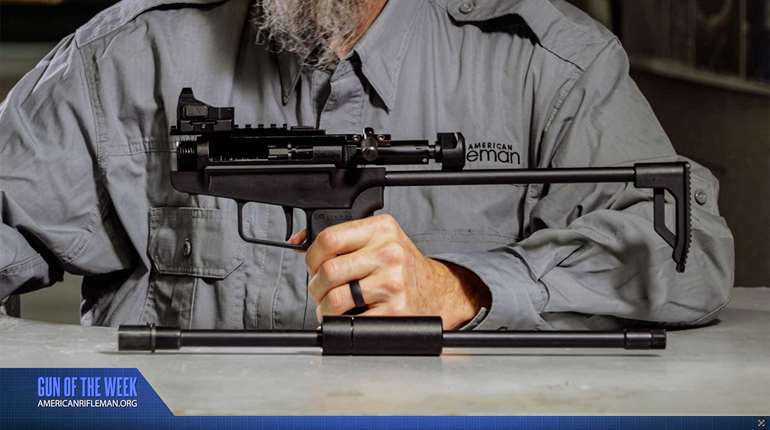

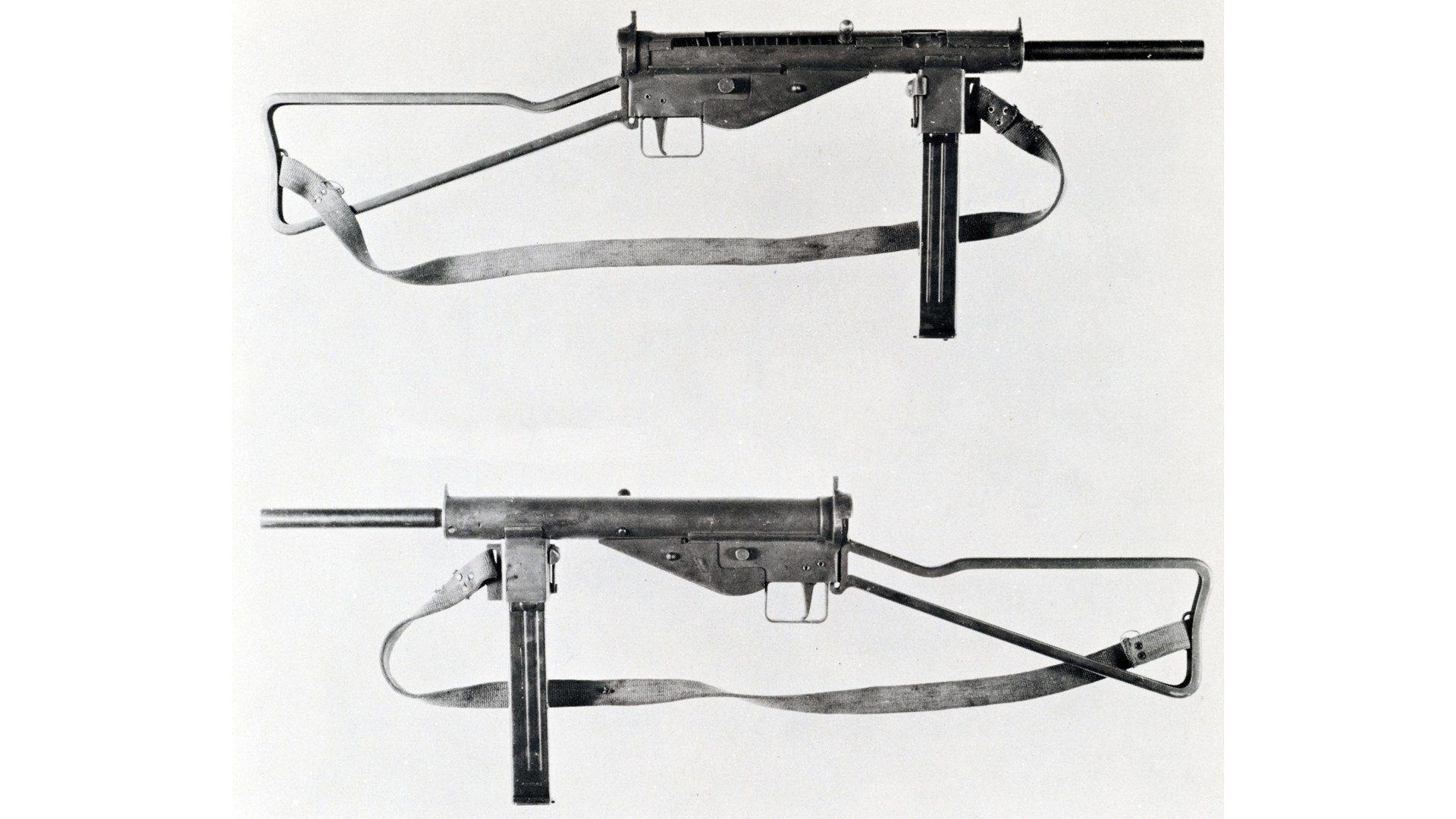

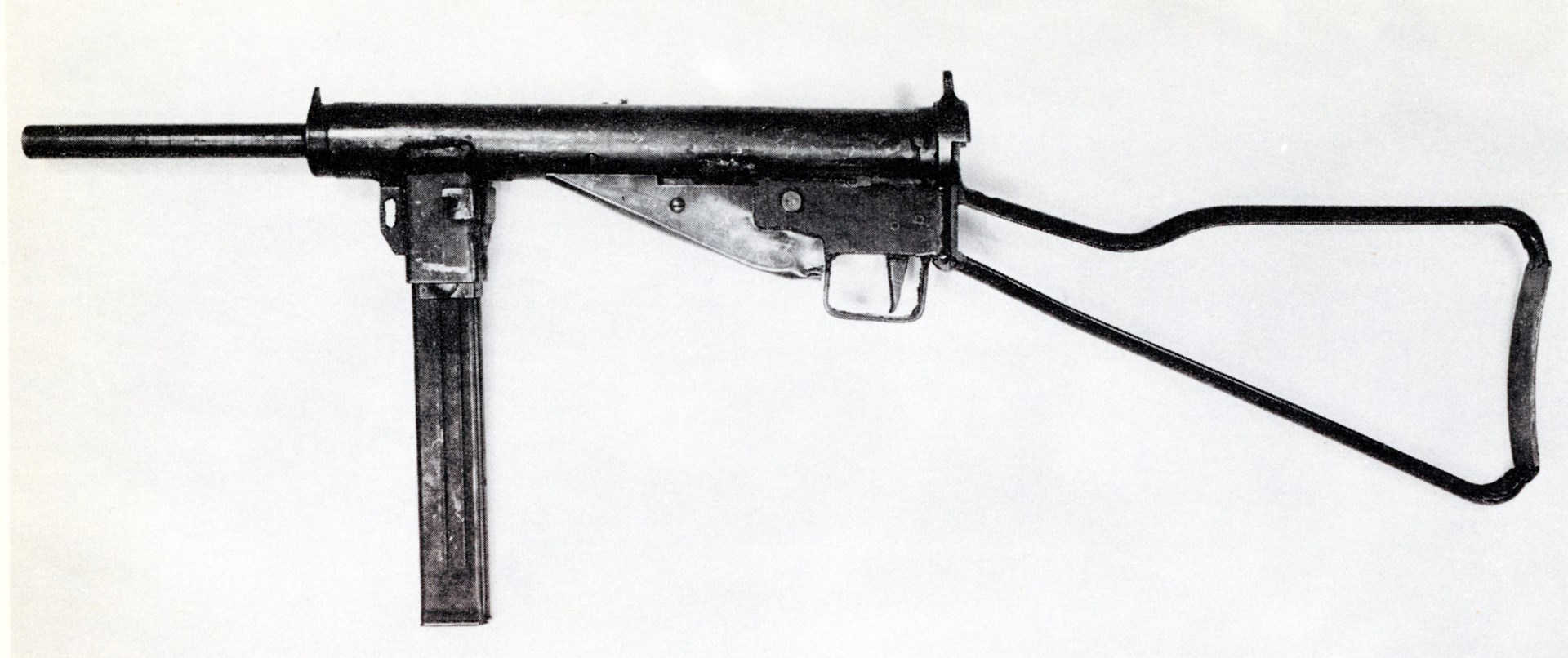

Immediately after their experience making copies of the Sten Mk II, Mauser would embark on a new Sten gun project. This time, the engineers at Mauser would find a way to simplify the Sten, further reducing cost and manufacturing time from the British standard, and even make the SMG appear more “German.” The new project was dubbed Gerät Neumünster, which later became the MP 3008, the “Volks MP.”

The first significant change was the use of a vertical magazine well, with the MP 3008’s magazine well welded directly to the receiver tube. This configuration revised the Sten’s normal horizontal magazine mount—creating a similar appearance to the MP40, and presumably more comfortable ergonomics for German shooters. The realignment of the magazine well brought on a second major revision to the original Sten design, the elimination of the barrel shroud. The shroud became unnecessary as the vertical well provided a convenient (and familiar) front grip. In another simplification from the British Sten, the trigger is permanently attached to the housing by staked pins.

An SMG In An Hour Or Less

It is hard to imagine that the Germans, much less the gunsmiths at Mauser, would purposefully create a firearm so crude as the MP 3008. But desperate times call for desperate measures, and by January 1945, Germany was almost out of money, manufacturing materials and was desperately short on time. Combining almost every manufacturing shortcut, and using the Reich’s geographically diffused production system, MP 3008 construction time was reduced to just a single man-hour of labor.

With components made in tiny shops, and then assembled by the workers in larger, more recognizable manufacturers, the German people’s submachine gun began to appear in the spring of 1945. Nazi leadership had set manufacturing goals of up to a million MP 3008s to equip the ranks of the Volkssturm, the German militia (controlled by the Nazi Party, and not the Wehrmacht).

By the end of the war, no more than 5,000 of the MP 3008 were made, and fewer than half of those were issued. Of the guns that survive today, markings and manufacturer’s codes are often confusing, with some impossible to identify, and some have no markings whatsoever. The first production variants were built to a slightly higher standard, and some featured a flat-plank wood stock. Just a few weeks later, MP 3008 quality would fall to previously unheard-of levels of fit and finish in German firearms.

Crude though it may be, the MP 3008 was nonetheless deadly, and the firearm might well have had a significant impact if it had been developed six months earlier. As it stands, the MP 3008 is a curiosity—a strange example of a simple machine gun made even simpler, hurriedly made in the Third Reich’s Götterdämmerung.

MP 3008 Specifications

Operation: blowback, open bolt

Cyclic rate: 450 rounds-per-minute

Magazine: 32-round MP40 magazine

Sights: front blade, rear aperture

The following is a report from the U.S. Ordnance Technical Intelligence team that inspected a MP 3008 and the facility in Solingen, Germany, that made it.

14 June 1945 RESTRICTED

ETO ORDNANCE TECHNICAL INTELLIGENCE REPORT NO. 316

SUBJECT: German 9 mm. Machine Pistol M. P. 3008 (German Sten).

Observations by: Capt. P. B. Sharpe, Ord. Tech. Intel., Hq. Com Z, ETOUSA, and 1st. Lt. E. M. Whitaker, Ord. Tech. Intel. Team 15. Photos by Ord. Tech. Intel. Team No. 1

General:

- Specimens of a new German 9 mm. Machine Pistol were recovered in the Karl Eickhorn Plant, in SOLINGEN, German, together with drawings and proof records indicating that the German designation of “M.P. 3008” has been applied to this weapon. It appears to be a simplified version of the British Sten 9 mm. Machine Pistol, designed with economy and speed of manufacture in view, stampings assembled by welding being used. The gun cannot be disassembled, and so accordingly was probably regarded as highly expendable.

- According to an employee of Eickhorn, only twenty-six of those machine pistols had been completed, although there is some evidence that this weapon was manufactured elsewhere, as a few of them have appeared in the field.

Description:

This weapon appears to be a simplified version of the British Sten, but shows one major change – the magazine is on the bottom instead of the side. While this makes possible excellent control from the shoulder and hip in weapons of this class, it is not convenient for firing from a prone position, as the magazine then interferes with the piece. There is a greater use of arc welding in assembly than in the British Sten, making it impossible to remove many of the parts for cleaning and replacement, although the gun may be field stripped. Selection of fire is achieved by a control button of the “push through” type. For full automatic fire, the control button pushes the sear to the right, disengaging it.

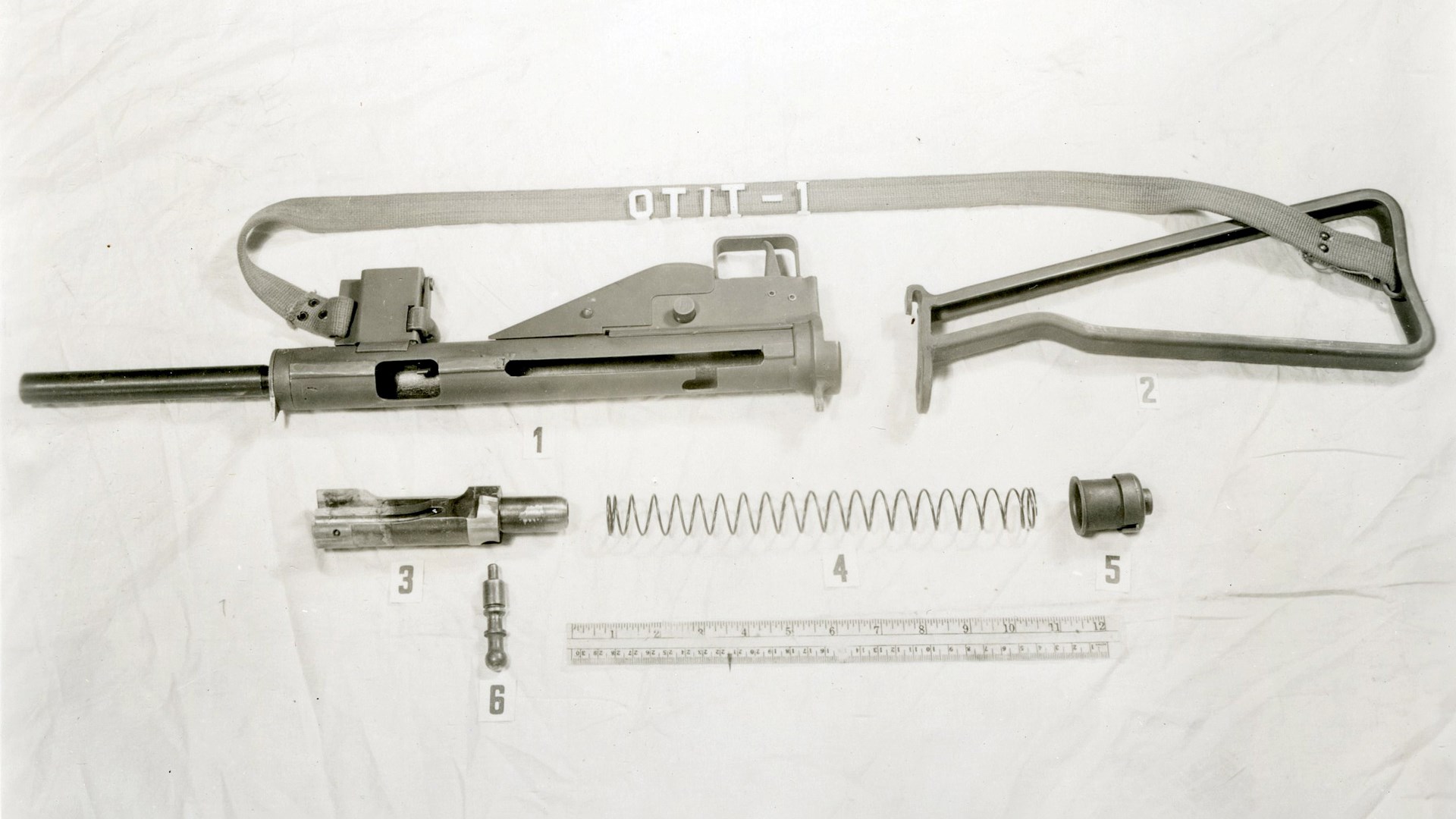

Field Stripping:

Depress the plunger in the center of the stock bracket. Remove stock by sliding downward. Push plunger in the receiver and while holding it in, rotate receiver cap on quarter turn to the right. The lugs on the receiver cap will then line up with receiver grooves and the cap will come free under the force of the recoil spring. Recoil spring may then be pulled free.

Retract bolt to the rear until a slot in the rear of the receiver is exposed. Align bolt handle with this slot and pull handle free. The bolt will then drop from the rear of the open receiver.

To assemble, reverse the above operations.