Today, Bill works with a handpicked team of smiths out of Fremont, Nebr. I'd drooled over their handiwork for years when at last I finally got the chance to write up a custom revolver review of my own. The team was kind enough to take photos at each stage of the work. So here's your chance to take a peek behind-the-scenes as this premier custom shop converts a classic Ruger Super Redhawk .454 Casull into an ideal multi-caliber field and hunting handgun.

Ruger's Super Redhawk double-action revolver in .454 Casull was released in 1997 as the first wheel gun in this caliber to feature a six-shot cylinder. Although the Super Redhawk arrives ready to work right out of the box, I was looking forward to C&S sprucing it up. My goal was to make it a more handy field and hunting gun by shortening the barrel from 7.5" to 6". This would give the beefy Super Redhawk a more natural balance and make it easier to carry.

C&S has a real gift for action jobs that smooth and lighten both double- and single-action trigger pulls. While it was there, the sight system would be upgraded and the wrist-bending recoil of .454 Casull loads would be reduced with in-line barrel porting. Last, but not least, the company offers an affordable cylinder modification that turns this version of the Super Redhawk into a four-caliber revolver.

Before the Super Redhawk arrived at C&S, I worked with the team over the phone to generate the detailed set of modifications, all of which are listed on the company website. The first step in the customization process was the removal of the front sight base. This was accomplished with the careful application of torch heat and pressure to release the sight mount from the barrel without warping either component. The barrel was carefully cut by hand to the desired 6" length.

Next, the factory stamped text on the left side of the barrel, the 'Read the Manual' disclaimer, was removed. The front end of the statement was cut away with the shortening of the barrel. The text on the right side, the words Super Redhawk, were still intact so they were left in place. This is a hand polishing process in which the gunsmith starts with draw files and works his way down to a fine polish using 400 grip sanding media.

The rough cut of the muzzle was milled and shaped to create an 11-degree crown. By using a special carbide tool rod, the cutters can be hand set to work the crown without removing the barrel from the frame. This reduces the time and expense in forming the crown, and any risk of damage to the frame or barrel threads removing the barrel would cause is avoided. Once the crown work was complete, the front sight base was re-welded to the barrel.

The C&S flat-line porting process effectively reduces felt recoil by redirecting some of the high-pressure gas produced by the cartridge through a series of ports near the muzzle. The gas travels upwards through the ports, pressing the muzzle down. As a result, the revolver doesn't kick quite as hard and there's less muzzle rise for quicker follow up shots. The trade off is that the porting makes the revolver’s report louder than it would be without them.

With the stout nature of .454 Casull ammunition, the reduction in recoil is worth the added noise. A caliber-specific tool aids the gunsmith in hand milling two flat lines into the curvature of the rounded barrel at either side of the front sight base. The round ports are then drilled into the barrel. The number of ports to be added is determined by the barrel length and the revolver's caliber. In this case, four ports were added on each side of the sight for a total of eight.

At the heart of this operation is the coveted C&S action job. Properly executed action work can significantly improve the feel and function of any handgun but it can make a marked improvement in the often heavy triggers of big-bore double-action revolvers. All of the small moving parts were removed from the gun. The contact points, where the parts move against each other or the frame, were taken through a three-step, hand-polishing process to remove any burrs or rough spots left over from the manufacturing process.

The contact points are first stoned, then sanded and finally finished with a high-speed polishing wheel for the smoothest finish possible. The factory trigger return spring and hammer spring were replaced. The result of this laborious process is a much smoother trigger with a reduced trigger pull. The double-action trigger pull dropped from somewhere over 12-lbs. to 10-lbs. 4-oz. That's impressive, but it was the single-action trigger pull that changed the most. It dropped from a serviceable 6-lbs. 1-oz. to a crisp, clean pull of just 2-lbs. 14-oz.

The Super Redhawk was embellished with electro-chemical engraving along the now blank left side of the barrel and the top strap. The use of stencils, etching compounds and a bit of electrical current create clean, consistent results without the added expense of sending the gun to an engraver. The words 'Cylinder & Slide' in script along the barrel proudly let folks know who provided the classy custom upgrades. The company logo on the top strap includes Bill's signature handlebar mustache.

With the barrel modification and internal work completed, the external surfaces and controls of the Super Redhawk received a two-stage bead blasted matte finish. The first stage is a garnet blast to give the surface the right texture. Because the garnet leaves the steel looking a little too dark, a second blast with fine glass completes the handsome low-glare, low-maintenance finish.

The 11-degree muzzle crown received a high polish finish, again by hand. The original factory sights were set aside in favor of a Bowen Classic Arms sight system. The rear sight is the company's Rough Country fully adjustable model with a flat face featuring a white outlined square notch.

Installing the front sight was a multi-step process. The Bowen Super Redhawk sight arrived as a plain solid metal blade sight. The sight height was corrected to match the height of the rear sight. Then the front sight was milled, drilled, and the front ramp was serrated at 50 lines-per-inch. The sight was then outfitted with a bright red fiber optic before it was installed in the front-sight base.

The last modification is one of my favorites because it converts this Super Redhawk into a four-caliber revolver. From the factory, this particular gun can safely fire the hot .454 Casull cartridge, standard pressure .45 Colt rounds and .45 Colt +P loads which generate energy levels somewhere in between .44 Mag. and .454 Casull. However, the cylinder and ejector star can be milled, or lathed, to make room for full moon clips that support .45 ACP cartridge cases.

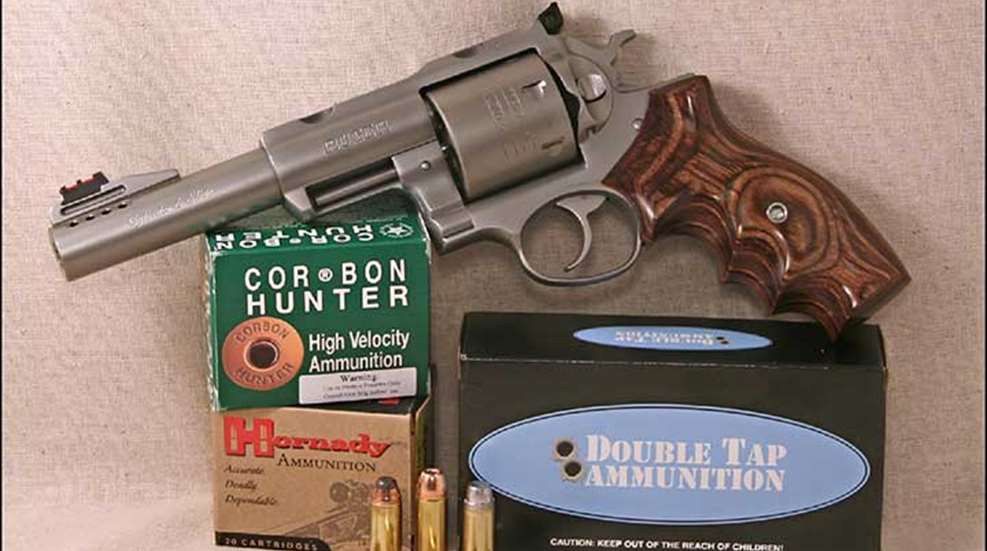

Being able to shoot .45 ACP can reduce ammunition costs with levels of felt recoil on par with standard pressure .45 Colt loads. When I got the revolver back from C&S, I traded out the factory rubber grip a Badger Custom Grips walnut finger-groove full grip to top off the handsome custom work.

I waited a long time to get a revolver re-worked by Cylinder & Slide, and I have to say that I'm extremely pleased with the results of the team's work. Some folks choose to hunt with single-action only revolvers because of their light trigger pull. The C&S action job made the single-action trigger pull of this Super Redhawk just as smooth and light as a single-action with all of the benefits and convenience a double-action revolver provides. Casual testing results are quite promising, so I'm looking forward to hunkering down at the bench and giving this gun a full workout.

Specifications:

Base Gun: Ruger Super Redhawk .454 Casull, 7.5" Barrel (#5505) $1,189

Cylinder & Slide Custom Work:

Barrel Shortening: 7.5" to 6", Front Sight Base Reattached $332

11-degree Muzzle Crown: $70

Barrel Porting: 4-Ports Per Side $227

Removal and Re-stamp: "Super Redhawk" On Right Side of the Barrel $70

Front Sight Upgrade: Bowen Super Redhawk Fiber Optic Front Sight $187

Rear Sight Upgrade: Bowen Adjustable Rear Sight $155

Action Tuning: $167

Cylinder Enhancement: Milled To Accept .45 ACP Full Moon Clips $140

Refinishing: Full Exterior 2-stage Bead Blasted Matte Finish $105

Cylinder & Slide Logos: Barrel and Top Strap - No Charge

Test Fire: $44

Grip Upgrade: Badger Custom Grips GP100 & Super Redhawk Full Grip, Walnut $90