Almost without exception, the oft-quoted, “There is no such thing as a free lunch,” holds true—especially when it comes to shooting. Sooner or later there’s a cost to be paid for every benefit gained, and typically that cost is not just monetary in nature. This is particularly true for velocity-craving riflemen who, even at the expense of additional recoil, report and cost, demand enhanced external ballistics from their cartridges and rifles. Fortunately, things have changed, and for the better.

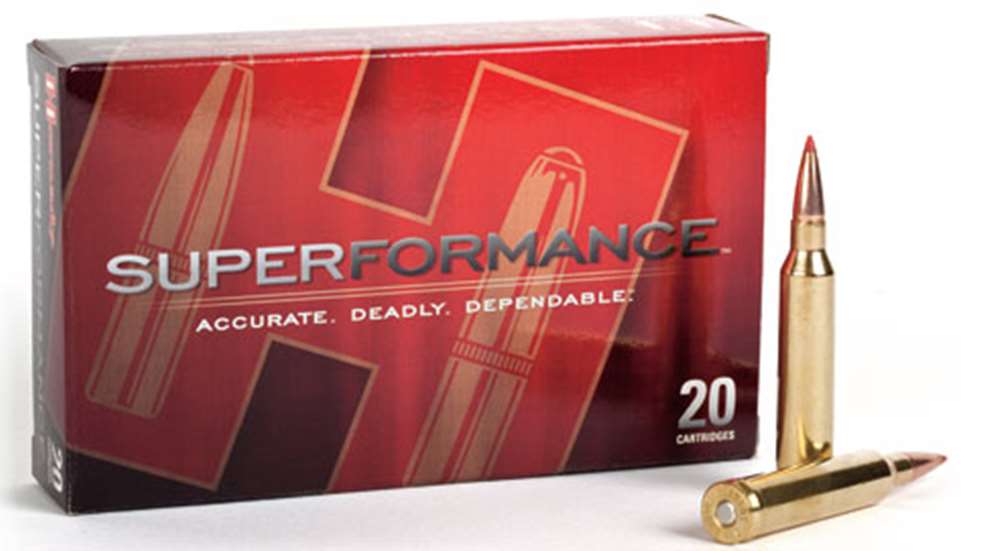

Hornady’s new Superformance ammunition not only rewrites the performance standards for popular center-fire rifle cartridges, but it also challenges the notion that, “There is no such thing as a free lunch.” How? Let’s find out.

Previous Practices: Increasing Performance Through Pain And Price

“In the past, small arms performance has been limited—particularly with lengthy, lead-free projectiles—by the propellant’s inability to be completely burned by the time the bullet exits the muzzle,” explained David Emary, Hornady’s chief ballistics scientist. “Until now, center-fire ammunition performance has been based on the IMR series of propellants developed in the 1930s and ’40s.”

As such, the ability to enhance external ballistics or, in some instances, attain Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI) standards, without exceeding established Maximum Average Pressures (MAP) has proved difficult, if not impossible. This is especially true with copper and gilding metal bullets, which not only occupy additional case capacity, thereby displacing propellant but, with longer bearing surfaces, also increase pressure.

Higher velocities have been, and still are, achieved primarily through the use of large, heavily compressed charges of slow-burning propellants, which also require solid crimping to prevent bullet migration. In its Mark V-series rifles, Weatherby further enhanced external ballistics through longer-than-normal freebore. Problem is, propellants used in such loads are of insufficient progressiveness, and therefore unlikely to be consumed before the bullet exits the muzzle—especially when using lightweight projectiles. The result: For a modest increase in velocity, the trade-offs are generally increased recoil and report, oftentimes lackluster accuracy, and higher ammunition prices. With its Light and Heavy Magnum-series ammunition, Hornady experienced these trade-offs, too.

Loaded via a dual-mechanical-compression procedure, not only was consistency difficult to maintain, but the process was also time-consuming and, requiring greater amounts of costlier propellants, forced prices significantly higher than those of the company’s Custom ammunition. With this, Light and Heavy Magnum was unsuitable for semi-automatic rifles and, according to Emary, “... resulted in fierce recoil and concussion ... .” It also proved finicky at times—especially when used in light-barreled and poorly bedded rifles.

Certain cartridges also proved problematic. “We never understood why, but with the 7 mm-08 Rem. and 7 mm Rem. Mag. Light and Heavy Magnum loads we struggled with accuracy,” said Emary. “We tried flat-base and boattail bullets but never got what we expected on a consistent basis.”

“Light and Heavy Magnum was something I wanted to address for a long time,” said Emary. And that he did….